Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

empty drums

What are the main reasons for hollow drums reinforced with carbon fiber fabric?

Before answering the question, we first look at a set of pictures.

1. The concrete is not smoothed before pasting;

2. The carbon cloth is not evenly pasted, and the air is not completely discharged when the scraper scrapes the cloth;

3. Different thickness when brushing carbon fiber glue;

4. After the carbon cloth is pasted, the topcoat is unevenly applied;

5. Quality problems of carbon fiber cloth, such as too hard, weaving is not tight, etc.

We can see that the first four factors mentioned above are all errors in the construction operation. As long as you pay attention, the problem of empty drums will not occur.

However, the quality of carbon fiber cloth is uncontrollable. Poor quality carbon fiber cloth will produce hollow. What factors will cause the quality of carbon fiber cloth to be bad? What does this have to do with empty drums?

The hollow drum problem caused by poor quality carbon fiber cloth is mainly due to three reasons. The tension of the carbon fiber tow is insufficient, the gap of the carbon fiber tow is inconsistent, and the raw material of the carbon fiber is poor.

The tension of the carbon fiber is not enough. After the glue is cured, some carbon filaments are straight, some are not straight, and the tension is not enough to form an empty drum. On the other hand, in many cases, the carbon fiber cloth is applied on the bottom, and the tow of the poor quality carbon fiber cloth is wavy. When the glue drops, the wave area becomes the falling point, which is called the empty drum

The carbon filament gap is inconsistent. There is a certain gap between the carbon filaments. If some filaments are tight and stick together, and some filaments are loose, hollowing will also occur;

The raw materials of carbon filaments are poor. Without good raw materials, there will be no good finished carbon cloth. It is inevitable to paste to produce an empty drum.

As a leading carbon fiber fabric manufacturer in China, how does Horse do?

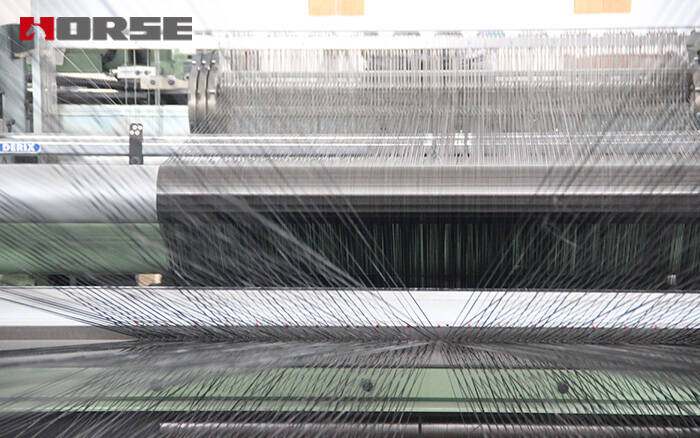

Independent developed constant tension system, ensures every bunches of raw fiber keeping constant tension. With low dispersion, high strength, stable properties, the qualification rate by national authority testing organization is 100%.

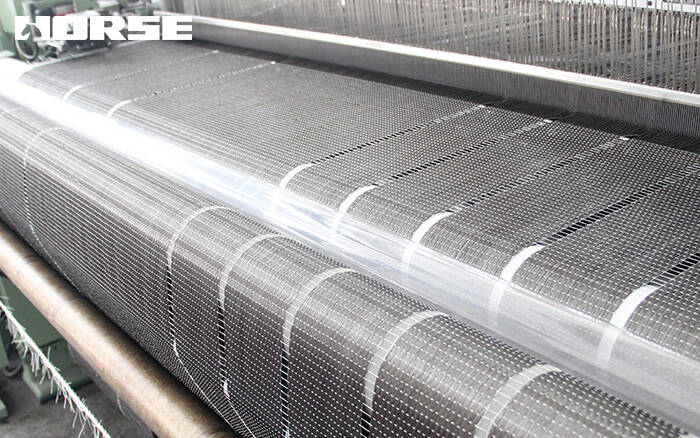

The carbon fiber fabric is woven evenly and smooth, moderate soft, good suitability with the impregnated adhesive, easy to impregnate, total adhesive usage used to 15% less than other suppliers’, and the hollow issues used to 80% less than other suppliers’.

Select the international high-quality aviation grade yarn, keep every carbon fiber yarn length over 5000 meters to ensure the continuity of the carbon fiber fabrics without damage raw fiber.

The hollow drum produced by the carbon fiber cloth will not only prevent the reinforcement from reaching the expected effect, but also increase the cost of the entire project, which will seriously affect the overall building safety. For safety reasons, it is better to use high-quality carbon fiber cloth for construction.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Low viscosity, strong penetration carbon fiber primer for reinforced concrete surface to enhace the defect part

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening