Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The seemingly ordinary FRP adhesive actually plays the dual role of impregnating fiber and bonded concrete, so today we will talk about the analysis of the performance and service life of FRP adhesive.

Life of FRP adhesive

The research on the life of impregnating adhesive is a key concept related to building safety.

According to the requirement of national standard for the service life of structural adhesives, the structural adhesives with a designed service life of 30 years should pass the test of moisture and heat aging resistance.

For structural adhesives with a design life of 50 years, they should pass the tests of moisture and heat aging resistance and long-term stress resistance, and for structural adhesives under dynamic loads, they should pass the tests of fatigue resistance.

Structural adhesives used in cold areas should be tested for freeze-thaw resistance.

For structural adhesives, its aging resistance is extremely important. First, the service life of building adhesives is required to be more than 30 years, and the bonding strength must be guaranteed in the later period. Secondly, the humid-thermal aging test adopted in the specification has a strong ability to detect bad curing agents, and the performance of curing agents determines the reliability of long-term use of adhesives.

Performance of FRP adhesive

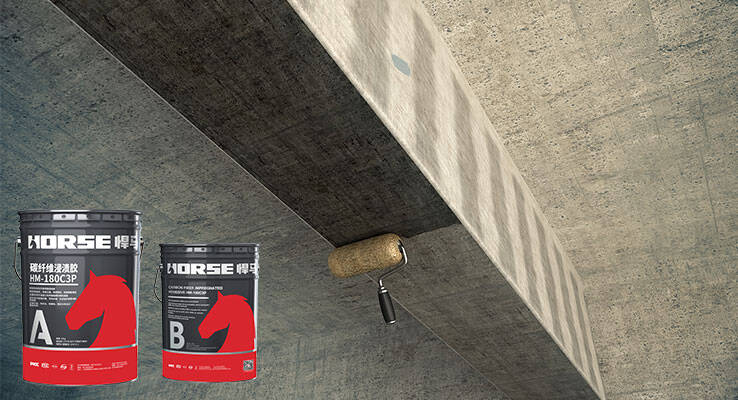

The fullness of coated carbon fibre impregnated adhesive is a factor affecting whether the carbon fibre can be fully effective stress. Usually, the use of carbon fibre impregnated adhesive ranges from 0.6 kg to 0.9 kg per square meter. The following problems often exist in the application of carbon fibre impregnating adhesives in practical projects:

When FRP adhesive are constructed on concrete facades, it will be difficult to guarantee the thickness of the adhesives between carbon fibre impregnation and concrete if the flowability is very serious. In addition, due to the reasons of flow, the surface will form a lot of gum tumors and gum pillars. It is easy to form hollowing phenomenon by sticking cloth. Of course, the effective bonding area of CFRP can not be achieved, which affects the reinforcement effect.

Therefore, on the basis of low viscosity and strong permeability, Shanghai Horse Construction impregnating adhesive ensures thixotropy of the glue through formulation improvement, so that it can penetrate into the surface of concrete and fibers well, reduce the generation of bubbles, and be easy to operate and save engineering costs.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Low viscosity, strong penetration carbon fiber primer for reinforced concrete surface to enhace the defect part

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening