Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

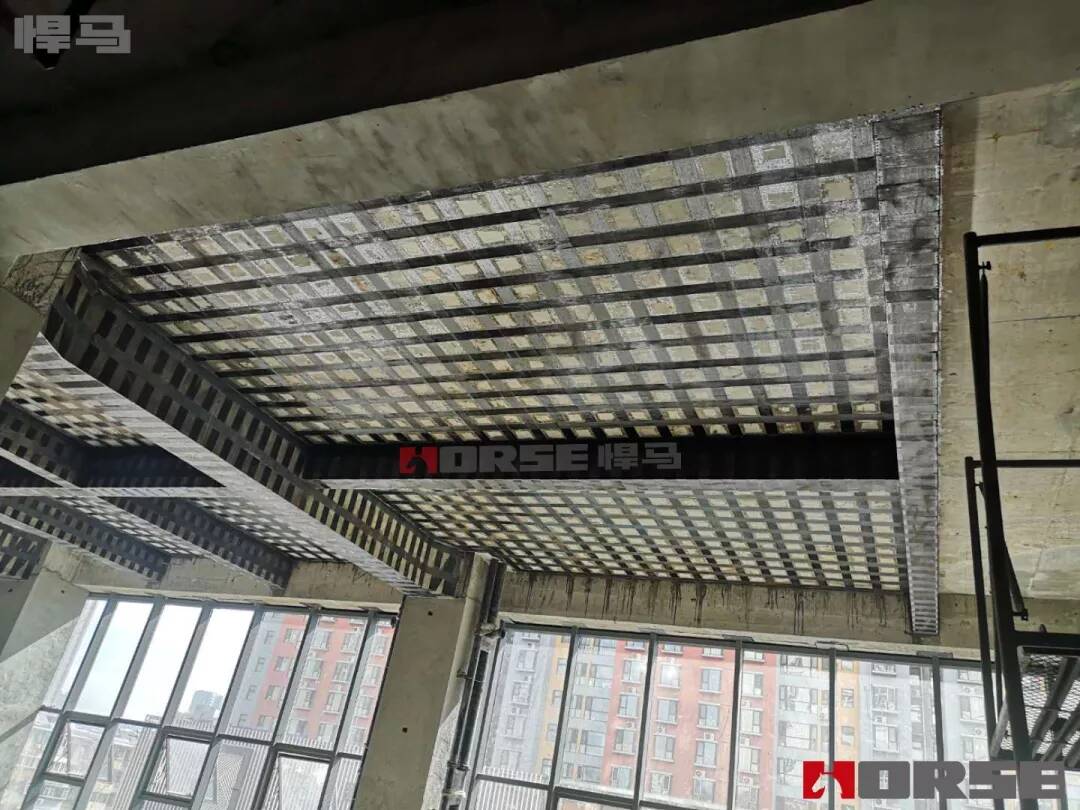

Everyone is familiar with the advantages of CFRP retrofitting. It has the characteristics of saving space, simple construction, easy construction quality assurance, basically no increase in structural size and weight, corrosion resistance, good durability and so on.

Everyone is familiar with the advantages of CFRP retrofitting. It has the characteristics of saving space, simple construction, easy construction quality assurance, basically no increase in structural size and weight, corrosion resistance, good durability and so on.

However, various problems and common quality problems will be encountered in the construction of carbon fiber wrap. How to prevent and deal with it? This article analyzes from the main reasons, prevention methods and treatment methods.

1. The surface plastering after CFRP retrofitting is affected.

The cement mortar layer is easy to fall off or the plastering operation cannot be performed.

main reason:

1. The cement mortar used for surface plastering has poor adhesion.

2. The surface of the carbon cloth is not roughened such as sanding.

Prevention method:

1. Select cement mortar with strong cohesive force. The mortar should be inspected on site. The wet-mixed mortar should be uniform in appearance without segregation and bleeding. The dry-mixed mortar in bulk should be uniform in appearance and free from clumping and moisture. The mortar should be completely packaged without moisture.

2. Before the dipping glue is cured, spray an appropriate amount of dry yellow sand on the outer surface of the carbon fiber.

2. Low bonding strength between carbon fiber and concrete base

main reason:

1. Reinforcement did not follow normal construction procedures and missed steps.

2. Improper sanding and cleaning of concrete surface.

3. The concrete surface is humid or the humidity in the air is high.

Prevention method:

1. Make technical explanations before construction to improve and standardize the skills of construction operators.

2. Repair and level the base surface first and then polish it. (Some areas with concave surfaces are prone to tensile stress after the carbon cloth is pasted, resulting in peeling.) Surface dust should be blown away.

3. The moisture content of the concrete base layer should not be greater than 4%, and should not be greater than 6% (the relevant moisture meter and other detection methods can be used). If the moisture content exceeds the limit, it can be dried by infrared irradiation or hot air. The humidity at the construction site is high. Ventilation and dehumidification should be performed to avoid large areas of wet work at the same time.

3. The adhesive is too thick for easy application

main reason:

1. During low temperature construction, epoxy resin is sensitive to temperature, and colloid thickening is normal.

Prevention method:

1. Before the construction process, heat the colloid with water bath heating.

2. Kappa customized (winter, low temperature) impregnated rubber products are selected, without heating the colloid to ensure normal construction.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.