Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The corrosion of the corroded damaged columns strengthened with FRP can be greatly reduced by corrosion, but the corrosion of the reinforcement in concrete can not be completely prevented.

In recent years, the corrosion resistance of reinforced concrete columns strengthened with FRP is summarized. The corrosion resistance of RC columns strengthened with FRP was studied in terms of corrosion current density, potential, chloride content and corrosion rate. Compared with traditional repair materials, FRP materials have the advantages of good corrosion resistance, stable performance and can improve the bearing capacity, deformation capacity and seismic performance of columns.

The good corrosion resistance of FRP reinforcement system in corrosive environment is related to its own performance. FRP reinforcement system is a kind of dense surface anticorrosive material with the ability to prevent moisture and oxygen from penetrating into concrete. Water and oxygen are two necessary conditions for steel corrosion in concrete. In previous studies, some scholars believe that the corrosion resistance of FRP reinforcement system is mainly due to resin, not FRP itself. In order to further understand the corrosion resistance mechanism of FRP reinforcement system and the role of FRP and resin in anticorrosion process, some scholars have systematically studied different FRP types, different FRP layers, different FRP fiber directions and different resin types. The study of these factors will help us understand the mechanism of corrosion resistance of reinforced concrete columns strengthened with FRP.

2.1 Effect of FRP species on corrosion resistance

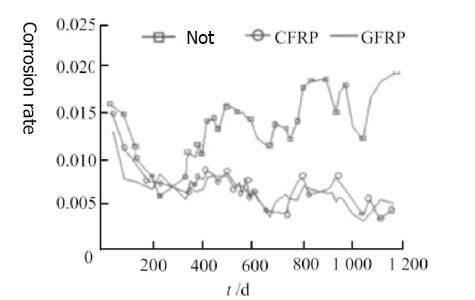

CFRP and GFRP are commonly used FRP materials in engineering. Some scholars have studied the corrosion resistance of reinforced concrete columns strengthened by CFRP and GFRP, and the difference between them. The corrosion resistance of two FRP materials was evaluated by potential, corrosion rate and steel weight corrosion rate. The average corrosion rate measured in the outdoor simulated natural corrosion test was shown in Fig. 1. The results show that the corrosion current density of the specimens protected by CFRP and GFRP is lower than that of the unprotected specimens, and the difference between them is not very great. The final corrosion rate of the two is compared, the difference between longitudinal reinforcement is only 0.1%, and stirrup is 0.3%.

| Specimen type | Standard specime | CFRP | FDRP |

Corrosion rate of longitudinal reinforcemen (%) | 6.6 | 3.3 | 3.4 |

Corrosion rate of stirrups (%) | 10.1 | 6.9 | 6.3 |

The results show that the corrosion current density of the CFRP and GFRP protected specimens is lower than that of the unprotected specimens during the whole test process, and the difference between them is not great. Literature studies show that there is no significant difference in corrosion resistance between CFRP and GFRP strengthened specimens. At present, there are no more comparative experimental results about the effect of FRP on corrosion resistance, so the influence of FRP on corrosion resistance needs to be further studied.

2.2 Effect of FRP layer on corrosion resistance

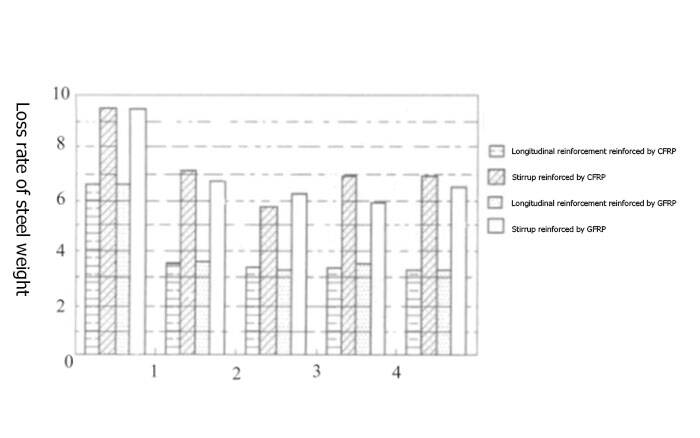

The number of reinforcement layers of FRP significantly affects the bearing capacity, deformation and seismic capacity of the structure. It is also an important factor in the study of corrosion resistance of corroded RC columns strengthened by CFRP. Many scholars have studied the effect of different layers on corrosion resistance. The corrosion resistance of corroded columns strengthened with 1 and 2 CFRP sheets was studied. The results show that the effect of increasing the number of CFRP on the corrosion resistance of the strengthened columns is not significant. The corrosion resistance of CFRP and GFRP columns with 1 to 4 stories was compared in the literature. Fig. 2 shows the final corrosion rate of FRP columns with different stories in the literature. From the results of the literature, it can be seen that the corrosion resistance of the columns strengthened with FRP is further improved when the FRP is increased from one layer to two layers. The corrosion resistance of the columns strengthened with FRP can not be further improved by increasing the number of FRP layers. The corrosion resistance of reinforced concrete columns strengthened with 1-3 layers of CFRP is studied in the literature. The experimental results show that the average daily corrosion rate of steel bars decreases by 29.07% when CFRP is increased from 1 to 2 layers. The daily average corrosion rate increased by 1.46% when the corrosion rate increased from 2 to 3 layers. If the error was taken into account, the anticorrosion effect of CFRP was almost unchanged when the corrosion rate increased from 2 to 3 layers.

2.3 Effect of FRP fiber orientation on corrosion resistance

In the field of FRP reinforcement, the direction of fiber and longitudinal reinforcement are different for different members and different reinforcement purposes. Some scholars have studied the effect of fiber direction on corrosion resistance. Corrosion resistance of CFRP columns strengthened with parallel, vertical and 45 degrees of longitudinal steel bars is studied in this paper. The results show that for the reinforced concrete columns strengthened with FRP, the anti-corrosion effect is better in the circumferential direction when the type of FRP, the thickness of the strengthened layer and the resin are the same, followed by the 45 degree axial direction, and the worst along the axial direction.

2.4 Effect of resin type on corrosion resistance

The resin used for FRP reinforcement has the ability of anti-seepage and air-blocking, and the anti-corrosion effect of the FRP reinforcement system formed by different types of resin adhesive and chemical composition is different. The corrosion resistance of CFRP strengthened columns with two different resin adhesives was studied. At the same time, in order to understand the role of resin glue in FRP anti-corrosion strengthening system, the corrosion resistance of the columns wrapped only with resin glue was studied, and the corrosion resistance of the columns strengthened with FRP was compared with that of the columns strengthened with resin glue. Table 2 is the results of the literature. The results show that the corrosion resistance of different resins is very different. The daily average corrosion rate of E1 resin is 1.65 times of E2, only 3.99% less than that of standard specimens, and 41.90% less than that of standard specimens. The corrosion resistance of FRP in E1 + FRP system is larger than that in E2 + FRP system. The corrosion resistance of FRP in E1 + FRP system is 39.48% lower than that in E1 + FRP system, while that of E2 + FRP is only 13.3% lower than that in E2.

| Type of glue | E1 | E2 | ||||

Reinforced | Unreinforced | Resin | Resin + fiber reinforced polymer(FRP) | Unreinforced | Resin | Resin + fiber reinforced polymer(FRP) |

| Daily mean corrosion /( % · d -1 ) | 4.01 | 3.85 | 2.33 | 4.01 | 2.33 | 2.02 |

By analyzing the factors affecting the corrosion resistance of FRP reinforcement system, we think that the influence of FRP types on the corrosion resistance of FRP reinforcement system needs further study. When the number of FRP layers is more than 3, the increase of the number of layers has little effect on the corrosion resistance of FRP reinforcement system. The direction of fiber also affects the corrosion resistance of FRP reinforcement system. Here, the mechanism of corrosion resistance of FRP reinforcement system is divided into material level and FRP confinement effect.

3.1 material level

The anti-rust mechanism of surface covering or coating material is waterproof penetration and preventing oxygen transport, both of which are necessary conditions for steel corrosion. As a kind of surface covering material, FRP's anti-corrosion mechanism is mainly embodied in this aspect. The anti-permeability and gas-resistance ability of FRP reinforcement system is provided by both resin and FRP itself. Under the condition of good anti-permeability and gas-resistance performance of adhesive resin, the anti-permeability and gas-resistance effect of fiber is not obvious.

3.2 FRP confinement effect

In the process of steel corrosion, the corrosion layer is thickened continuously. Under the condition of no external restraint, the corrosion can overflow from the corrosion crack, and the corrosion around the steel bar is very loose. After strengthening with FRP, the encapsulation of FRP prevents the rust from overflowing, and the rust around the steel bar prevents further contact between water and oxygen and the steel bar, thus slowing down the corrosion of the steel bar to a certain extent. In addition, the restraint effect of FRP restricts the corrosion expansion of steel bar, reduces the cracking of concrete protective layer, prevents the water from entering, and delays the corrosion of steel bar.

For the two mechanisms of FRP reinforcement system, the main role is the anti-permeability and gas resistance of FRP reinforcement system, which is the common performance of resin and FRP itself. In the case of good impermeability and gas resistance, resin alone can play a good anticorrosion effect. In the case of poor impermeability and gas resistance of resin, FRP can make up for the deficiency of resin, and ultimately achieve good anticorrosion effect. FRP constraints indirectly reduce the transport of oxygen and water, and this mechanism plays a limited role, only a supplementary role.

4 Conclusion

Based on the experimental study of the main factors that affect the corrosion resistance of FRP reinforced structures, the following conclusions are drawn:

4.1 The corrosion of the corroded damaged columns strengthened with FRP can be greatly reduced by corrosion, but the corrosion of the reinforcement in concrete can not be completely prevented.

4.2 The corrosion resistance of corroded RC columns strengthened with CFRP and GFRP has no significant difference, but the difference of other FRP corrosion resistance needs further study.

The anticorrosion effect of CFRP is almost the same when the fiber cloth is increased from 2 to 3 layers. The anticorrosion performance of corroded RC columns is affected when the FRP layer is increased from 1 to 2 layers. The direction of fiber also affects the corrosion resistance of corroded RC columns. When FRP is used to reinforce corroded RC columns, the anti-corrosion effect of fiber direction is better, followed by 45 degrees, and the axial direction is the worst.

4.4 The types of resins seriously affect the corrosion resistance of corroded reinforced concrete columns strengthened with FRP. In the case of good impermeability and air resistance of the resins, resin alone can play a good role in corrosion protection. In the case of poor impermeability and air resistance of the resins, FRP can make up for this deficiency.

4.5 The anti-corrosion mechanism of FRP reinforcement system is mainly the reflection of the anti-permeability and anti-gas ability of resin and FRP itself. The restraint effect of FRP plays a certain role in the anti-corrosion performance of FRP reinforcement system.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.