Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber wrap structural reinforcement technology

Several failure forms of carbon fiber wrap structural reinforcement

(1) The tensile steel bar reaches yield first, and then the concrete in the compression zone is crushed. At this time, the carbon fiber wrap has not yet reached its allowable tensile strain.

(2) The tensile steel bar reaches yield first, and the carbon fiber wrap has exceeded its allowable tensile strain and reached the ultimate tensile strain and broke. At this time, the concrete in the compression zone has not been crushed.

(3) Due to the excessive reinforcement of the carbon fiber wrap, the concrete in the compression zone is first crushed before the tensile steel bar reaches yield.

(4) Before reaching the bearing capacity of the normal section, the carbon fiber wrap and the concrete base surface have peeled off.

The working principle and characteristics of carbon fiber wrap reinforcement technology

It is difficult for the carbon fiber filaments in the carbon fiber wrap to work together completely. When bearing a lower load, a part of the carbon fiber filaments with higher stress first reaches their tensile strength and exits the working state, which causes the carbon fiber filaments to gradually break until the whole is destroyed. But after using the binder, the carbon fiber filaments can work well together, greatly improving the tensile strength of the carbon fiber cloth. Therefore, the binder plays a key role in the reinforcement of the carbon fiber wrap. It not only ensures that the carbon fiber filaments work together, but also ensures that the carbon fiber wrap and the structure work together. The tensile material is pasted on the tensile side of the structure to share the force with the structure, strengthen the reinforcement, and achieve the purpose of reinforcement.

Application engineering of carbon fiber cloth structural reinforcement

Project example

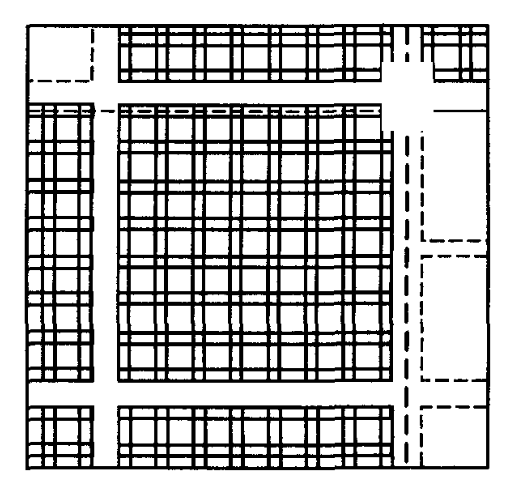

After the construction of the comprehensive office building in the depot of Guangzhou Metro Line 4, according to the owner's requirements, the use of some rooms needs to be changed, and restaurants need to be added. The original design room panels cannot meet the load requirements of the restaurant, and structural reinforcement is required. After comparing the schemes, a carbon fiber wrap is glued to the bottom of the board in two directions to improve the bearing capacity of the board, as shown in Figure 1.

Conclusion

The comprehensive building of Guangzhou Metro Line 4 depot adopts carbon fiber wrap structural reinforcement technology, which fully reflects its advantages. During the construction of the project, only simple scaffolding was used on the premise of ensuring safety. Moreover, carbon fiber wrap is very convenient to cut. It can be cut at will according to the shape and size. It can be passed through at the shelter of various supports, and the construction is very convenient. The construction period is greatly shortened, and the construction cost is also quite low in comparison.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.