Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber plate

Structural reinforcement

Structural reinforcement, such as the use of external prestressing, the pasting of steel plates in the tension zone of the structure, or the addition of steel structural supports. In recent years, the use of new structural reinforcement materials-carbon fiber composite materials to replace steel plates has caused significant changes in reinforcement technology.

The principle of carbon fiber composite reinforcement

1) Carbon fiber reinforced reinforced concrete bending members.

The flexural reinforcement of reinforced concrete flexural members is to replace or supplement the tensile performance of steel bars by pasting carbon fiber in the tensile area of the member, thereby improving the flexural bearing capacity of the member. After the carbon fiber is pasted, the strain of the carbon fiber is small before the concrete cracks in the tension zone of the component. After the concrete cracks, carbon fiber gradually participates in the joint work, and the strain growth accelerates. After the steel bar yields, the carbon fiber plate is fully functional, and its high-strength and high-efficiency performance is fully reflected.

2) Carbon fiber reinforced reinforced concrete shear members.

The shear reinforcement of reinforced concrete is to paste carbon fiber into the shear area of the component, where the role of carbon fiber is similar to stirrups. Before the component yields, the strain of carbon fiber develops slowly, and the maximum strain value reached is also small. After the component yields, the role of the stirrup is gradually replaced by carbon fiber, and the strain development of carbon fiber is accelerated, and the strain value is higher than the strain value of the stirrup, while the restraining effect of the stirrup is reduced, and the strain develops slowly.

3) Carbon fiber reinforced reinforced concrete seismic column

The main function of carbon fiber is to restrain its internal concrete. This kind of restraint is a passive restraint. With the increase of the axial pressure of the concrete column, the lateral expansion promotes the circumferential elongation of the outer carbon fiber cloth, thereby increasing the lateral restraining force. The restraint mechanism depends on two factors: the transverse expansion performance of concrete and the hoop restraint ability of the outer carbon fiber. The concrete confined by carbon fiber cloth shows a two-stage stress process: in the first stage, the concrete is in a linear elastic stage similar to plain concrete, with small lateral deformation, so the lateral deformation of carbon fiber is also very small, and the boundary point is near the peak stress of the concrete. In the second stage, after the component reaches the ultimate bearing capacity, the transverse expansion and deformation of concrete increase sharply, the hoop strain of carbon fiber increases significantly, the hoop restraint force increases, and the ultimate compressive strain of concrete increases, thus delaying the crushing of the concrete in the compression zone. The plastic deformation performance of the longitudinal steel bars is exerted, and the ductility of the components is significantly improved.

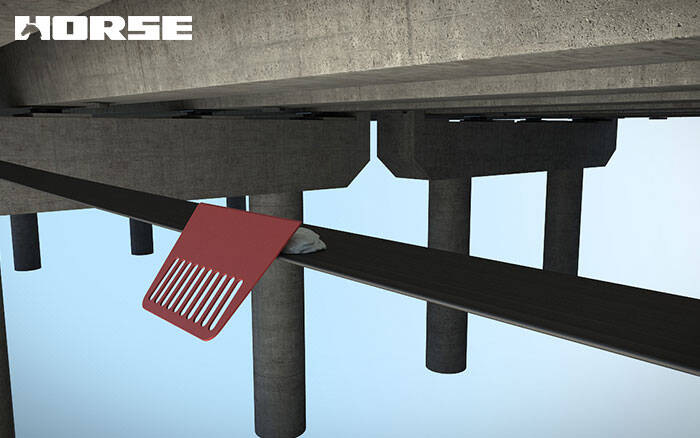

Application of carbon fiber plate reinforcement technology in bridge reinforcement

Carbon fiber plate material characteristics

①High strength and high efficiency. The tensile strength of carbon fiber sheet is generally above 3500MPa, which is much higher than that of steel. The tensile modulus of elasticity is 230,000-430,000MPa, which is also higher than that of steel. Therefore, its specific strength (that is, the ratio of the material's strength to its density) can reach more than 2000MPa/g/cm3, while the specific strength of Q235 steel is only about 59MPa/g/cm3, and its specific modulus is also higher than that of steel.

②Light weight and good flexibility. Carbon fiber has high specific strength and quality is only one-fifth of steel. It has high toughness, can be coiled, and can be supplied in a larger length without overlapping. And does not increase the dead load and section size, does not reduce the clearance under the bridge

③Convenient construction and easy guarantee of construction quality. The material does not need to be pre-processed, the process is convenient, and the plates are allowed to cross.

④ Good durability and corrosion resistance. It is resistant to acid, alkali, salt and atmospheric corrosion and does not require regular maintenance.

Structural adhesive requirements

Requirements: The adhesive has high tensile and shear strength, good toughness, corrosion resistance and aging resistance. All technical indicators of building structural adhesives exceed the requirements of "Technical Regulations for Reinforcement and Repair of Concrete Structures with Carbon Fiber Sheets".

Carbon fiber plate reinforcement process

(1) Treatment and repair of concrete adhesive surface. First, use an angle grinder to remove the 1-2mm thick surface. After polishing, use compressed air to blow off the floating dust. Finally, wipe the surface with a absorbent cotton cloth moistened with acetone, and wait until it is completely dry. For the honeycomb, pitted surface, and recessed parts of the concrete surface, the formwork joints are repaired and filled with a spatula to reduce the height difference. After the repair glue is cured (it is advisable to feel dry to the touch), the next process can be carried out.

(2) Unloading (according to the actual situation and design requirements, this step is sometimes omitted). Carbon fiber reinforcement has the best effect with moderate unloading. Generally, live loads are removed. The live loads on components such as personnel and office equipment should be temporarily removed, and temporary construction loads should be minimized. For load unloading, a system consisting of jacks, backing plates, and ejector rods can be used. The reaction force applied by the system is easy to control, so that the post-adhesive fiber and the original component can be forced together, and the construction efficiency is high.

(3) Configure sticky dipping and cutting carbon fiber plate. The configuration method is the same as the configuration of primer and primer. The amount of each configuration should be less than 3kg, ready to use; cut the carbon fiber plate according to the size required by the design.

(4) Paste the carbon fiber plate. The bonding resin is prepared according to the process regulations provided by the product manufacturer, and the surface of the carbon fiber plate should be wiped clean to no dust. When two layers need to be pasted, both sides of the bottom carbon fiber plate should be wiped clean. The cleaned carbon fiber plate should be coated with bonding resin immediately. The resin layer should be protruding and the average thickness should not be less than 2mm. The carbon fiber plate coated with bonding resin should be lightly pressed by hand to the position to be pasted. Use a rubber roller to compact evenly and smoothly along the fiber direction, so that the resin is extruded from both sides to ensure compactness and no voids. When multiple carbon fiber plates are pasted in parallel, the gap between the two plates should not be less than 5mm. When two layers of carbon fiber plates need to be pasted, they should be pasted continuously. When it cannot be pasted immediately, the bottom carbon fiber plate should be cleaned again before pasting.

(5) Curing. The structural adhesive can be cured well at room temperature and low temperature. If the curing temperature is about 25°C, it can be loaded and used in 4 days. If the curing temperature is about 5°C, the load can be used within 7 days.

(6) test. During the inspection, you can use a small hammer or hand pressure to judge the paste effect. The total effective bonding area should not be less than 95%. If there is slight hollowing, the needle can be injected with glue to remedy it. Load detection can also be used for important components. Generally, the standard value of loading to normal load is adopted. The test results are more intuitive and reliable, but the cost is higher. It is necessary to prepare jacks or counterweights (commonly used sandbags, bricks), dial indicators, crack microscopes, and weighing instruments.

(7) maintain. After 48 hours of pasting, it can be painted with 20mm thick M15 cement mortar or sandblasted for protection, and it is not necessary to treat dry environments.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.