Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Cracks and their expansion are the precursors of structural damage and collapse, and cracks reduce the bearing capacity of the structure. So structural strengthening system is needed.

The vertical cracks on the sides of the reinforced concrete beams and cracks on the tortoise are shown in Figure 1. The characteristics of this kind of crack are that the vertical crack is generally equal to the length of the beam, and the height of the crack is much more in the middle of the beam and high school.In severe cases, the depth of cracks can reach 100 - 200mm, and more severe cracks occur. Cracks often occur on the upper and lower edges of beams, and are not evenly distributed along the beam length, and the depth of cracks is shallow, which is surface cracks.

The cause of the cracking: the reason for the vertical crack is that the concrete is not watered enough when the concrete is cured, especially when the mold is not cured. It is easy to take place in summer construction. It is a dry shrinkage crack. The cause of the turtle crack is that the template water is not enough, especially when the water is not wet through the wood model.

Control treatment: for this kind of crack, the crack width is less than 0.1mm, the width of the crack is 0.1 ~ 0.3mm for surface sealing treatment; the crack width is 0.3 ~ 1.0mm with epoxy resin slurry; the crack width is more than 1.0mm, the micro expansive cement slurry can be repaired. Before repair, a layer of water should be painted on the surface of the crack. Mud interface agent. For the more serious tortoise cracks, the loose part should be removed and chiseled because of the low strength of concrete and even the peeling off angle, and the high strength cement mortar should be embedded.

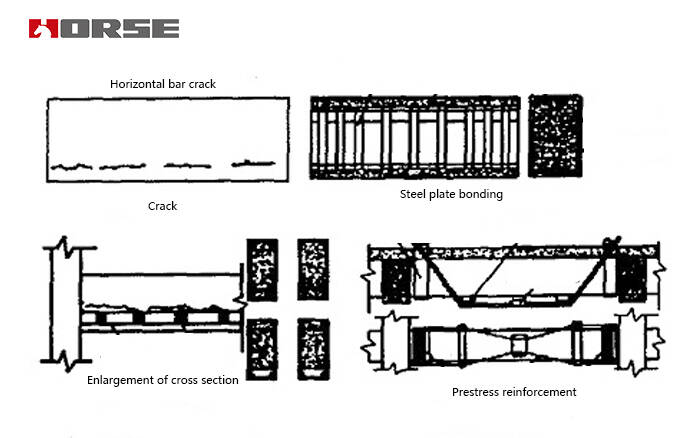

The horizontal reinforcement cracks of reinforced concrete beams are shown in Figure 2. The characteristics of this kind of crack are that the cracks are in the same direction as the reinforcing bar, and they appear on the reinforced concrete beams which have been used for a period of time.

The cracks are caused by corrosion of steel bars and expansion of iron oxide, and further thin concrete protection layer, using chlorine containing admixtures, corrosive gas or liquid invading concrete in the environment, such cracks are common in industrial buildings. The cracks in the horizontal bar of reinforced concrete beams will lead to the reduction of the bond rate between the reinforced concrete and the concrete, and even the safety and durability of the structure. Therefore, the reinforcement and reinforcement should be carried out.

Precautionary measures include: when the design is designed, the thickness of the protective layer should be increased; in the course of construction, the reinforcement skeleton is fixed and the lower part of the main reinforcement is added to ensure the thickness of the concrete protective layer; the admixture without chloride is used, and the reinforced concrete beam is treated and maintained.

Strengthening treatment: in general, the cracks are first embedded with epoxy mud, and then the reinforcement. Method: steel jacketing, the reinforcement of the prestressed horizontal bar, the reinforcement of the prestressed pull rod and the reinforcement of the steel plate and so on.

The cracks at the concentrated load of reinforced concrete beams are shown in Figure 3. The characteristics of this kind of cracks are diagonal cracks on both sides of the secondary beam at the junction of secondary beams and main girders, which belong to load cracks.

Reasons for cracks: low strength of concrete in design or construction, insufficient reinforcement for designing stirrups or reinforcement, and upward reinforcement during construction.

Preventive measures: Design transverse reinforcing steel bar according to the specification. During construction, the quality of concrete construction and the accuracy of steel bar location should be guaranteed. Such cracks usually need to be reinforced. Treatment method: strengthening measures by sticking steel plate reinforcement technical measures.

The diagonal cracks on the upper ends of reinforced concrete beams are shown in Figure 4. This kind of crack feature: the crack is distributed in the upper part of the main beam, and the crack is inclined to the crack, and the width of the crack is small in the upper mouth of the upper mouth, and the cracks appear most after the work is used.

The cause of the crack is that there is a strong constraint on the two ends of the main beam, for example, the upper end of the thin abdominal beam has a rigid sky window frame on both ends of the thin abdominal beam. As the sky window frame and the thin abdominal beam are buried at both ends of the beam, when the thin abdominal girder is deformed under the load, a certain bending moment and shear are produced at both ends of the beam, causing cracks at the end of the beam.

Preventive measures: a certain number of structural reinforcement is installed at the beam end. Treatment method: under normal circumstances, reinforcement measures are taken by sticking steel reinforcement technology.

The negative bending cracks of reinforced concrete continuous beams are shown in Figure 5. The characteristics of this kind of crack are that the cracks appear near the supporting part or at the junction of primary and secondary beams. The width of the cracks is large and small, and the ends of the beams are closed at the main reinforcement of the beams.

The reason for cracks is that the negative bending moment of reinforced concrete beams is too large, resulting in the negative bending moment cracking.

Preventive measures: a certain number of structural reinforcement is installed at the beam end. Treatment method: strengthening measures by sticking steel reinforcement technical measures.

The vertical cracks and diagonal cracks of reinforced concrete beams are shown in Figure 6. The characteristics of this kind of cracks are that vertical cracks appear in the middle part of the beam span, and the vertical and oblique cracks of reinforced concrete beams appear at both ends of the beam; these cracks appear mostly in the construction stage or in the use stage, which are typical load cracks.

The cause of the crack: there are two main reasons for the design and construction. The factors such as the improper selection of the design section size, the insufficient reinforcement of the main reinforcement and the insufficient reinforcement of the cross section can lead to the vertical cracks and slanting cracks in the reinforced concrete beams, and the actual strength of the concrete is low and the main tendons are pulled on the main tendons in the construction. The factors such as floating or less discharge, less horizontal stirrup in oblique cross section and overloading of construction load will also lead to vertical and oblique cracks in reinforced concrete beams, and such cracks will be produced by excessive load. The vertical and oblique cracks of reinforced concrete beams are typical load cracks, which will endanger the safe use of the structure. Therefore, it is necessary to find out the causes of the cracks and strengthen the reinforcement and treatment for different conditions and harm degree.

Treatment methods: in general, first, the cracks are embedded with epoxy mud, and then the do technical measures, such as the reinforcement of the steel, the reinforcement of the reinforced concrete, the reinforcement of the prestressed horizontal rod, the reinforcement of the prestressed pull rod, the reinforcement of the steel and the reinforcement of the U shaped hoop, are used.

The lamellar cracks in the compression area of reinforced concrete beams are shown in Figure 7. This kind of crack characteristics: cracks appear near the compressive area of reinforced concrete beams, and horizontal cracks and vertical cracks interweave, forming a mesh.

The cause of the crack is that the reinforcement of the reinforced concrete beam is insufficient and the design section size is unsuitable. In the construction, the concrete strength is low, the main tendons of the compression zone are shifted or less, the construction load is overloaded and the load is too large, and the cracks will also be produced. The layered cracks in reinforced concrete beams in compression zone are typical load cracks, which will endanger the safe use of structures when they are serious.

Treatment method: under normal circumstances, reinforcement measures are adopted in the compression area by sticking steel reinforcement technology.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack