Slab crack repair

Strengthening fibre reinforced polymer(FRP) system and crack injection adhesive

Decided to adopt carbon fiber reinforced polymer system(CFRP) for strengthening. A layer of carbon fiber fabric with a width of 600 mm is pasted on the bottom of the slab.

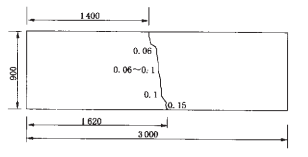

Because of the increase of external load, the flexural bearing capacity of the floor slab is insufficient. The floor cracks and the maximum crack width is 0.15MM, which affects the normal use of the users. Therefore, it is necessary to reinforce the reinforced concrete floor slab.

After comprehensive analysis and comparison of various reinforcement schemes, it is decided to adopt carbon fiber reinforced polymer system(CFRP) for strengthening. A layer of carbon fiber fabric with a width of 600 mm is pasted on the bottom of the slab.

Firstly, the cracks are grouted or sealed according to the design requirements, and then the next step is performed after the grouting material reaches a certain strength.

Materials: epoxy injection crack repair

The concrete surface at the bottom of the slab is grinded with grinding wheel or angle grinder to remove the surface loose layer and oil stains and other impurities until a new concrete interface is completely exposed, and the surface floating ash is removed with compressed air.

The primer resin is evenly coated on the concrete surface with roller brush.

The adhesive layer thickness should meet the design requirements and should not be too thin. After applying the soaking resin, the carbon fiber fabric which has been cut down according to the design requirements can be quickly pasted into place within the specified use time of the product. When bonding CFRP sheets, special rollers are used to roll and extrude bubbles several times along the stress direction of CFRP sheets, so as to make CFRP sheets adhere closely to the concrete surface, and at the same time make the adhesive penetrate into the gap between the fibers. Finally, the carbon fiber cloth is covered with plastic film for protection.

After at least 8 hours, remove the plastic film, coat the surface of carbon fiber cloth with a layer of base resin, and dry the base resin, then apply cement mortar to the surface.