Beam and slab strengthening

Carbon fiber reinforced polymer(CFRP) wrap reinforcement

In addition to the traditional methods of enlarging cross-section and wrapping steel, some new strengthening methods have appeared in recent years, such as prestressing FRP strengthening, shotcrete, bonding steel and carbon fiber reinforced polymer(CFRP) wrap reinforcement.

With the rapid development of China's economy, large-scale engineering construction is growing. In the process of construction, the quality of the project is not up to the standard because of the low technical level or the inadequate management, and various quality problems appear. In the existing buildings will also encounter this situation, a long-term use of the main structure of a project in the case of damp or vibration loads will also lead to concrete spalling, steel corrosion, and so on, resulting in a significant reduction in structural resistance. When the structural load changes and the original structure can not meet the strength or stiffness requirements, it is necessary to detect and strengthen the structure or components. In addition to the traditional methods of enlarging cross-section and wrapping steel, some new strengthening methods have appeared in recent years, such as prestressing FRP strengthening, shotcrete, bonding steel and carbon fiber reinforced polymer(CFRP) wrap reinforcement.

The technology of strengthening and repairing concrete with CFRP is to reinforce the original structure by bonding CFRP fabric to the surface of the structure. Generally, it is suitable for the tension parts of slabs and beams, shear parts of beams and columns and piers, parts with insufficient anchorage length of reinforcing bars, reinforcement of columns and piers, and bending, shear and tensile reinforcement of roof trusses. Carbon fiber is also widely used in various industrial and civil buildings, structures, anti-seismic, anti-cracking, anti-corrosion reinforcement. Compared with traditional reinforced concrete or steel-bonded concrete, carbon fiber has the advantages of space saving, simple construction, no need for site fixing facilities, easy construction quality assurance, no increase in structural size and weight, corrosion resistance, good durability and so on. In addition, the adoption of this method can greatly improve the service life of buildings and reduce the cost of reinforcement. Therefore, carbon fiber has attracted much attention as an epoch-making reinforcing material.

1 design principle of reinforcement

In the calculation of concrete beams and slabs strengthened with CFRP, the effect of concrete in tension zone is neglected. The average strain of concrete, CFRP and steel after bending conforms to the assumption of plane section, and the linear elastic stress-strain relationship is adopted for CFRP. According to the assumption of plane section, the strain of carbon fiber should be slightly greater than that of reinforcing bar. To simplify the calculation, the tensile strain of carbon fiber can be approximately equal to that of reinforcing bar. According to the principle of equal tension, the area of CFRP can be transformed into the equivalent area of steel bars, and then the equivalent area of steel bars can be obtained.

2 project example

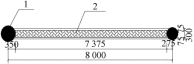

For a palace project in a tourist area, the formwork support has not been calculated, and the horizontal and vertical connecting rods are unreasonable, resulting in insufficient stiffness of the support. When the concrete strength has not reached a certain strength, the deformation of the formwork support increases due to the influence of floor load, and the floor slab produces excessive deflection, resulting in cracks. The honeycomb phenomenon occurs at the bottom of the middle span of some frame beams during concrete pouring, which seriously affects the bearing capacity. After on-site exploration, the honeycomb position of unqualified frame beams is strengthened by patching materials, and the floor slabs with cracks in flexure are strengthened by pasting carbon fiber to restore the original design bearing capacity.

3 reinforcement scheme

1) for beams and slabs with honeycomb and pockmarked surfaces, the following methods can be used to repair:

A. determine the concrete repair area.

B. Cut out the loose concrete in the repair area, clean up the dust and debris in the area until the hard concrete is exposed.

C. repair concrete surface with concrete patching material (brush interface, plaster, calender, etc.).

D. Watered or covered with plastic bags in time after 1-2 hours of repair operation, and kept the surface wet for 2-3 days.

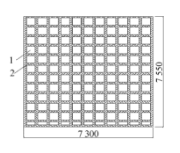

2) slab reinforcement: for the larger flats, the method of reinforcing the bottom of the slab with two-way bonded carbon fiber sheets is adopted.

4 construction technology

Carbon fiber material specification: single layer thickness is 0.167 mm, tensile strength is not less than 3400 MPa, tensile modulus of elasticity is not less than 2.3 x 105 MPa, elongation is not less than 1.6%.

5 Summary

Carbon fiber reinforced concrete beam-slab structure in this project fully utilizes the characteristics of carbon fiber cloth, which is a new material. It can be seen that carbon fiber reinforced concrete construction is simple, simple and safe, does not occupy space, can effectively improve work efficiency, shorten the construction period and so on. At the same time, the quality of reinforcement is effectively guaranteed, the stability of the reinforced concrete structure is stable, the bearing capacity is guaranteed, and good economic and social benefits are created.