Steel plate bonding project

Restore the original strength of the building structure. It can be completed in a short time.

The reinforcement practice of the project shows that the reinforcement of damaged reinforced concrete structure by sticking steel profiles is quick and convenient in construction, low in cost and high in bearing capacity, which can provide reference for similar projects in the future.

The reconstruction of the North tributary of Zhu'e River needs a reinforced concrete closed frame structure at the north end of Liuzhou Railway Station of Hunan-Guangxi Railway. The top of the frame is about the thickness of the soil, and the jacking method is located in the karst development area. When the stalagmite is blasted in construction, the foundation of a railway shoulder retaining wall pile which was placed above the stalagmite is destroyed. After the frame is jacked in, the foundation pile sinks and damages the roof of the frame. The damaged surface of the frame is about the same width and length as its roof. The concrete is broken and destroyed partly. The block is slightly dislocated. The reinforcement bars are exposed, deformed and corroded.

The project should be used before the rainy season. Due to the rainy season, the construction period is urgent. It will take a long time to reinforce the frame with adhesive fiber composite material, and the construction can not be completed before the rainy season. If the method of enlarging cross-section is adopted, the cross-section of the frame will be compressed, which can not meet the design flood discharge requirements. After comparison and selection of various schemes, it is decided to adopt the fast construction method of bonded steel reinforcement to reinforce the damaged frame, that is, to treat the damaged reinforced concrete frame roof, to paste steel plate at the bottom of the plate and weld the steel section, so as to make it and the original reinforced concrete as a whole and bear the force together.

Restore the original strength of the building structure.

The original strength concrete of restorable structure is brittle material, once broken, it will lead to the loss of design bearing capacity of concrete. The purpose of reinforcing and strengthening cracked concrete structures is to restore the bearing capacity due to cracking. The frame has large roof thickness and large amount of reinforcement, so it is seriously damaged. However, by pressing bonding materials, the broken concrete can be reconnected as a whole, and the joint bearing force with steel bars is designed to compensate for the loss of concrete damage, and the steel plate is attached to the surface of the tensile side of the concrete structure. At the same time, the profiled steel is welded on the bottom of the steel plate so that the new profiled steel body, steel plate and the original reinforced concrete can bear the same load together, thus restoring or exceeding the strength of the concrete structure before it is damaged, and meeting the requirements of the bearing capacity of the structure and the service state.

It can be completed in a short time.

It can be completed in a short time because of the short setting time of bonding materials, the steel plate and section steel are processed quickly, and the general construction period is about half a month, so it can be completed in a short time.

Reinforcement method

Construction preparation

Before the construction, the technical status of the frame shall be reviewed and reinforcement design shall be carried out according to the re examination results. At the same time, material inspection, instrument calibration and equipment calibration should be carried out to meet the requirements. Before dealing with the cracks, the broken concrete blocks of the surface layer should be cleaned up to keep the old concrete surface wet, clean, straighten out the bending deformed steel bars, weld and restore after removal, and remove rust treatment and other defects of the surface layer of reinforced concrete after treatment should be in the repair area and the surrounding brush penetrating rust inhibitor.

Crack treatment

Crack treatment should be based on different components, locations, crack morphology, select appropriate repair methods, materials and sequence. The repair method of the project is pressure perfusion. In repairing materials, polymer fine stone concrete is used for larger cracks, and special crack adhesive for engineering is used for smaller cracks. The safety performance index of repairing material shall conform to the relevant regulations of polymer cement grouting material for crack repairing and adhesive for crack repairing. The construction process of pressure perfusion: surface treatment of seam. Paste the grouting nozzle and discharge nozzle. Seal the seam. Sealing inspection. Grout. Closure check

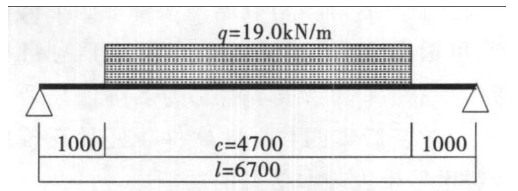

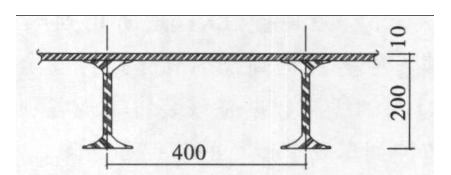

Pasting steel plate and welding I-beam

Structural checking must be carried out before steel plate and welded I-beam are bonded, including the determination of design load, the checking of the bearing capacity of the steel beam and the bolts at the end of the beam. The project uses anchor bolts to anchor and paste the steel plate plum blossom shape on the concrete slab.I-beam is welded with equal spacing on the bonded steel plate. Continuous bilateral fillet welds are used in the weld. The thickness and welding process of the weld should meet the design requirements so as to integrate the I-beam and the steel plate. I-beam is anchored to the side wall of reinforced concrete frame by ordinary bolts at both ends of the beam to meet the shear resistance requirements of both ends of the beam.

Rustproof and anticorrosive Department

The project is a drainage structure, long-term humidity environment, must use appropriate coating materials to ensure that the section steel and steel plate reinforcement has sufficient durability. The reinforcement works use anti rust paintbrush surfaces on all exposed surfaces of steel. After the welding of the steel structure is completed, the zinc rich antiseptic can be brushed to meet the structural durability requirements.

Concluding remarks

The drainage frame used in the North tributary of Zhu'e River crossing the railway was damaged in the construction process. The reinforcement of the damaged structure was completed in less than time by bonding steel plates to weld profiled steel. The drainage frame was put into use as scheduled. The reinforcement practice of the project shows that the reinforcement of damaged reinforced concrete structure by sticking steel profiles is quick and convenient in construction, low in cost and high in bearing capacity, which can provide reference for similar projects in the future. The project has been in good condition since it was put into use in May 2009. But because the frame structure will be in humid environment for a long time, its anti-corrosion and anti-rust effect should be further observed.