Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

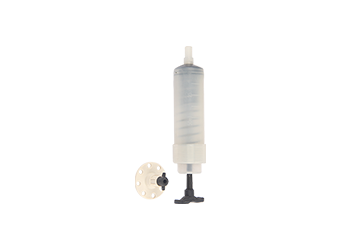

Introducing Horse HM-120L Concrete Crack Repair System

The construction Process of HM 120L crack injection Adhesive

First, chip away plastering of the range on each side of crack by 10cm. Sloppy along crack according to design, then polishing and cleaning it up. Sealing creaks and ports with structural repairing adhesive, keep ports distance 10 to 30 cm. When the structural repairing adhesive has cured, precedes the air pressure testing if there is leakage, see less or reinstall ports. Mix the horse construction crack injection adhesive according to the ratio. Stir evenly and avoid any bubble. Inhaled the adhesive with adhesive injector and inject adhesive via ports one by one. Start the second injector when adhesive overflow from one side to the other side. When crack injection adhesive has initial cured, remove injectors and ports. Level the surface with structural repairing adhesive, take the quality inspection after 7 days.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack