Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

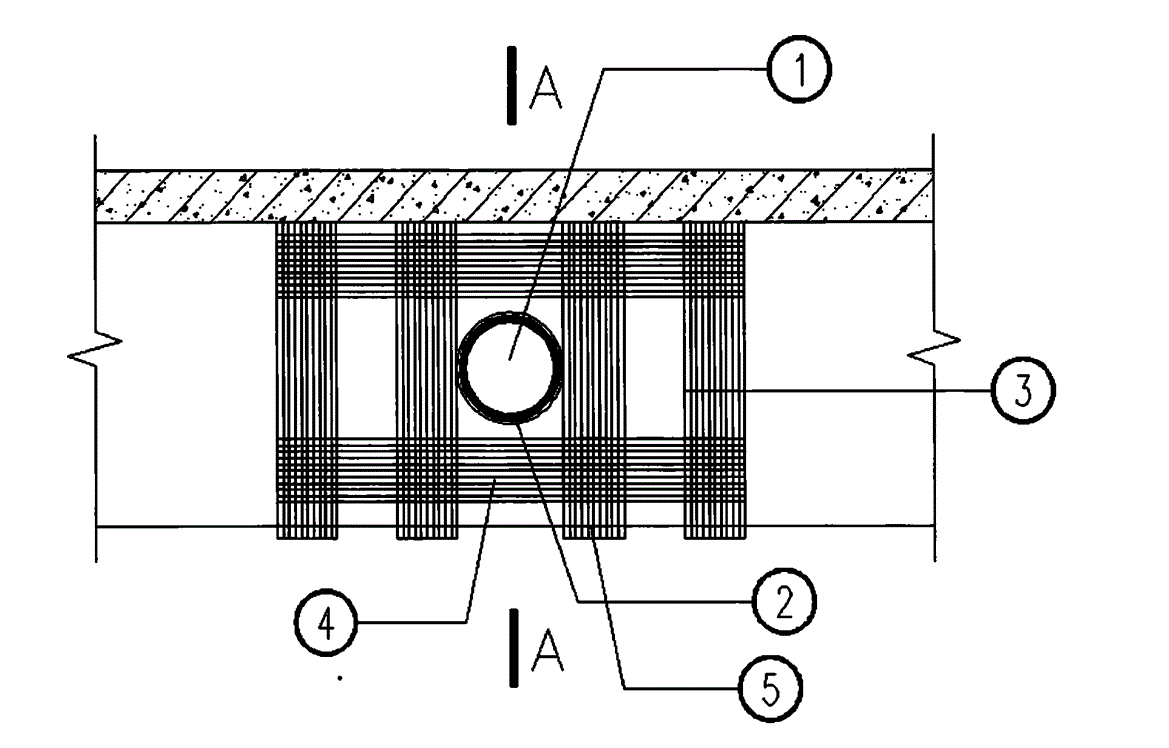

Carbon Fiber Reinforced Beam Opening

During the decoration, because of the need to make holes in the structural beam due to water and electricity routing, many owners are nervous and afraid of affecting the safety of the house. So, how to deal with this situation?

The main basis for judging the potential safety hazard caused by the opening to the beam is the degree of damage to the main reinforcement and stirrup in the beam.

(1) Main reinforcement is not broken

If the opening is small and the main reinforcement is not broken, some stirrups may be broken. This situation also has an impact on the structure, but it has little impact on the main bearing capacity of the structure. In addition, the structure has considered a certain safety factor in the design, so it can not be strengthened.

(2) Break part of main reinforcement

If the opening breaks part of the main reinforcement, which will affect the safety performance of the beam to some extent, it is considered to use the reinforcement method of pasting carbon fiber cloth or pasting steel plate for reinforcement. The specific reinforcement scheme shall be calculated by contacting the professional design unit.

Note: In this case, we must pay attention to it as soon as possible, and the earlier it is reinforced, the better, so as to avoid regret in case of accidents.

(3) Break all rebar

When opening, all the main reinforcement will be broken, which is equivalent to degenerate into plain concrete beam, and the bending bearing capacity will be greatly reduced, which is quite dangerous. As the pasted steel plate or carbon fiber cloth is not suitable for the reinforcement of plain concrete or members with reinforcement ratio less than 0.2% on one side of longitudinal load-bearing reinforcement, the method of planting reinforcement and increasing the section can be adopted in this case. The specific reinforcement amount also needs to be calculated by professional design unit.

Although it is not allowed to destroy the structure privately under any circumstances, it is recommended to consult a professional design company first in case of unavoidable circumstances, and do not operate blindly.

What requirements need to be met for opening on the beam?

1. Before opening, it is necessary to understand the house structure and internal and external conditions, and understand the intention of each hole location;

2. After determining the opening position, mark each hole position and observe the direction of water and electricity pipelines;

3. When opening, it is recommended to hit on the top or both sides of the beam, because these positions bear the minimum force;

4. The opening shall be made on the beam with wall below as far as possible;

5. Try to open small holes on the beam;

6. If the beam height is 20cm, upper and lower holes shall not be opened;

8. The opening of the beam shall avoid damaging the reinforcement as much as possible. It is strictly forbidden to drill holes at the 5cm lower part of the beam, because generally there are main reinforcements at the 3cm lower part of the beam, which will affect the bearing capacity;

9. It shall be opened in the middle of the beam span as far as possible, and it must not be opened at both ends of the beam;

10. Do not open a hole near the junction of primary and secondary beams;

11. The lower edge of the opening shall be at least 10cm away from the beam bottom to avoid damaging or breaking the reinforcement at the beam bottom; 10cm is only for the beams of residential buildings. If the beams with larger span and section are encountered, they should be farther away;

12. Keep a certain distance between the opening and the upper edge of the beam or the bottom of the slab.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.