Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Key Points Of Strengthening Construction Technology Of Prestressed Carbon Fiber Plate

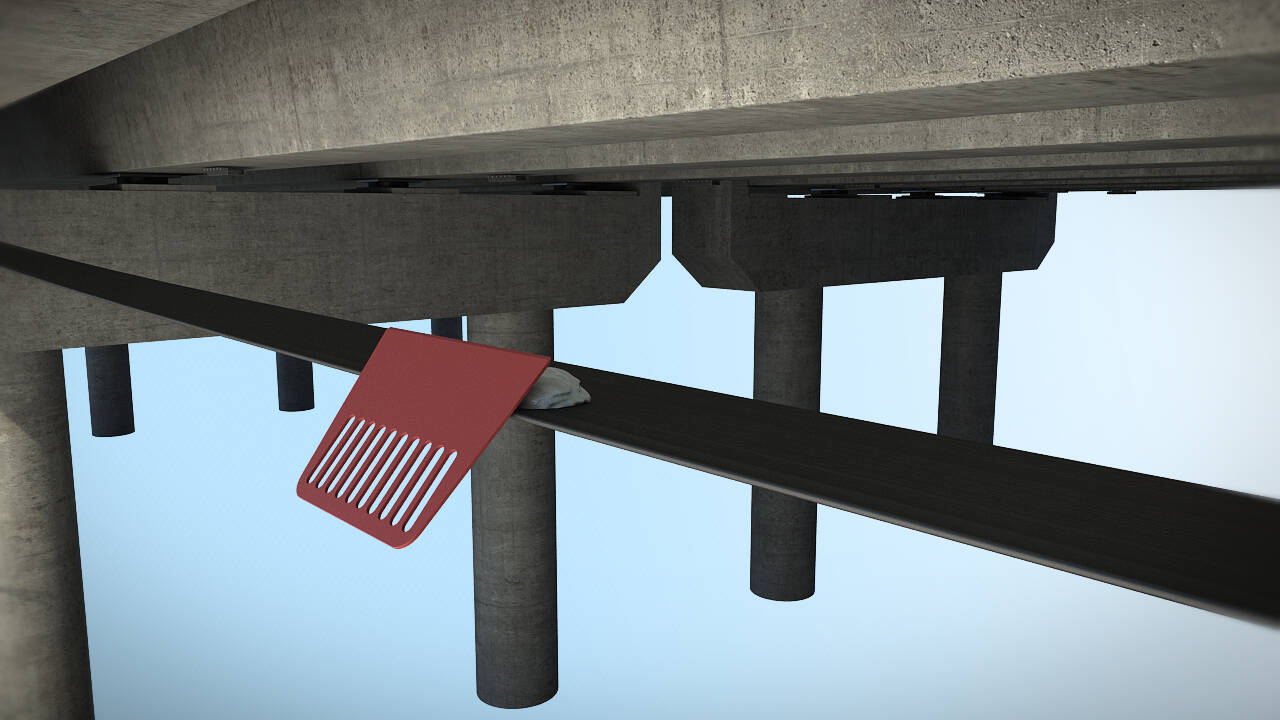

Prestressed CFRP Plate strengthening technology belongs to active strengthening technology, which is a new type of CFRP strengthening technology. Combined with the high strength of carbon fiber plate and the characteristics of applying prestress, carbon fiber plate has high strength utilization rate. While significantly increasing the strength and stiffness of the structure, it can reduce the deflection and deformation of reinforced concrete structures, reduce and close cracks, and has the advantages of light deadweight, little damage to the structure, simple construction, and good reinforcement effect.

In the maintenance and reinforcement project, the reinforcement effect mainly depends on the quality of the reinforcement materials and the standardization of the reinforcement construction. In this issue, we will discuss some construction points that are easy to ignore but directly affect the reinforcement effect in the process of the prestressed carbon fiber plate reinforcement construction. Welcome to exchange your comments.

01

Drilling and rebar planting

The main function of planting steel bars is to fix and limit the tensioning end, anchorage device at the fixed end, and battens, so as to prevent the prestressed carbon fiber plate from eccentric tension, fracture, anchorage device separation, etc. during the tensioning process, and ensure smooth and safe tensioning.

drill hole

First of all, before drilling, the ink box shall be used to pop up the installation position line of the base and the layering according to the design requirements, and the fixed position of the drilling shall be marked at the bottom of the concrete beam. The steel bar detector shall be used to detect whether there are stressed steel bars or the original prestressed steel strands of the beam at the predetermined drilling position. In case of distributed load-bearing reinforcement, the drilling position can be adjusted according to the horizontal margin of the fixed hole position on the base to avoid damage to load-bearing reinforcement and prestressed steel strand.

Drilling shall be carried out in strict accordance with the cross center point of the positioning mark to minimize the deviation error. The drilling machine and drill bit shall be selected according to the diameter of the anchor bolt and the hole depth to ensure the perpendicularity and depth of the hole.

Hole cleaning

If there is dust in the hole, it will affect the bonding ability between the planting glue and the concrete hole or anchor bolt, and affect the anchoring bearing capacity of the planting rebar. Therefore, the hole cleaning treatment is also extremely important. It is recommended to use a blower and a hard brush to clean the hole. The hard brush should be deep into the hole bottom, rotated back and forth for many times to clean the hole, and then the blower should be deep into the hole bottom to clean the dust. Repeated cleaning should not be less than 3 times until there is no floating dust in the hole. If necessary, cotton yarn and alcohol should be used to clean the hole wall.

Planting reinforcement

Inject the rebar planting glue to about 2/3 of the hole depth, implant and rotate the anchor bolt in a single direction until the glue overflows, and the anchor bolt should be perpendicular to the beam surface.

02

Installation inspection of carbon fiber plate

Carbon fiber plate is carbon fiber reinforced unidirectional plate. Its molding process is to cure carbon fiber impregnated with resin in the mold and continuously pultrusion. Therefore, the shear and bending strength of the cross section (width direction) is low.

After the installation of carbon fiber plate, if the center line of carbon fiber plate and the center lines of anchors at both ends are not on the same axis, with the increase of prestress, it will lead to uneven stress of carbon fiber plate and increase cohesive shear stress, which will lead to longitudinal damage of carbon fiber plate.

Therefore, pre tensioning shall be carried out before formal tensioning, and the pre tensioning shall reach 30% of the design tensioning control stress (see the design requirements for details). The anchor center extension line detection method shall be used to check whether the anchor center lines at both ends deviate and adjust, and adjust the carbon plate to the appropriate position.

03

Tensioning protection

Before tensioning, protective measures shall be taken. Carbon fiber plate is brittle material. If the tensioning operation is improper, splitting, fracture and other situations may occur. In addition, with the support of huge prestress, there is a great danger. Therefore, protective measures should be taken during the construction process, and the operation should not be carried out directly below the carbon fiber plate axis to avoid danger.

GB 55034-2022 General Code for Safety, Health and Occupational Health on Building and Municipal Construction Sites (implemented since 2023.6.1) clearly stipulates that when tensioning and dismantling prestressed structures, protective measures shall be taken at the prestressed ends, and there shall be no construction workers in the axis direction.

04

Graded tensioning

Some construction units choose to complete all tensioning at one time or maintain the pressure and load for too short a time when conducting formal tensioning, which will lead to failure to find out problems that affect the tensioning effect (such as eccentric tension and fracture of carbon fiber plate, anchorage breaking, etc.) in time, leading to tensioning failure and even danger.

Therefore, it is necessary to conduct staged tensioning, and the specific staged tensioning stress value and corresponding elongation shall comply with the design drawings. When the tensile stress value and elongation of carbon fiber plate meet the requirements, the pressure and load shall be maintained for about 5~10 minutes (refer to the design specification for specific requirements), and the tensioning nut shall be fully locked, paying close attention to whether there are abnormal conditions on the tensioning and fixing ends and the original structure. In case of any abnormality, the tensioning shall be stopped immediately, and the technician shall check the cause of the abnormality. If necessary, the pressure shall be relieved, and re pressurization can be carried out only after the problem is solved.

After tensioning, if there are no other abnormalities, the tensioning tooling can be removed. At the same time, tighten the bolts on the batten to ensure that there is no gap between the carbon fiber plate and the batten.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) strip for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) laminate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.