Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Comparison Of Commonly Used Structural Reinforcement Methods For Bridges

Common reinforcement methods

In order to improve the fatigue resistance of the existing concrete bridges, improve the vibration performance and increase the live load reserve, it is necessary to increase the bearing capacity and strengthen them. At present, the commonly used reinforcement methods to increase the bearing capacity mainly include the following:

1) External prestress reinforcement method

The external prestressed reinforcement method is to arrange metal external cables or ribs with anti-corrosion protection measures and FRP (Fiber Reinforced Polymer) on the outside of the beam. It is an active reinforcement method that offsets the bending moment and shear force generated by part of the external load by pre-adding the external prestress, thereby improving the bearing capacity of the beam. This reinforcement method changes the stress state and internal force distribution of the original structure of the beam, and has the triple effect of strengthening, unloading, and changing the internal force of the structure. So as to achieve the purpose of improving the bearing capacity of the bridge and improving the structure's crack resistance and durability, the improvement of the bearing capacity of the bridge can reach 30% to 40%.

This reinforcement method is the simplest and most economical way to improve the bearing capacity of the bridge. It has the following advantages:

① Suitable for reinforcement of large and medium-span bridges;

② It is easy to check, repair and replace, and the pre-stress can be adjusted quickly and conveniently;

③ The external reinforcement and the beam are only connected in the anchoring area and the turning area, and there is friction loss only in the local contact area, and the total loss of prestress is small:

④ It can effectively improve the stiffness of the bridge, the limit bearing capacity and the fatigue resistance of load stress, reduce the deflection in the middle of the span, and improve the vibration performance:

⑤ It can be applied to bridge reinforcement projects on a large scale, and the reinforcement system is easy to realize mass production;

⑥ The reinforcement cost is relatively low;

⑦ Reinforcement construction takes a short time and has little impact on traffic:

⑧ The increase in the self-weight of the bridge can be ignored, and the bearing effect of the pier and abutment is not increased;

⑨ Reinforcement construction will cause little damage to existing bridges;

⑩ It is convenient to install sensing elements on the external prestressing system to meet the needs of long-term real-time health monitoring of prestressing and bridge structures.

But there are also some disadvantages:

① The external cable is only connected to the beam body in the anchoring area and the turning area. Once the connection part fails, the consequences are serious, so the safety and reliability of these two parts are required to be high;

② There is still a large stress concentration in these two areas, and the force status is more complicated, which causes certain difficulties in design calculation and analysis;

③ The long-term friction between the steering block and the external cable easily damages the cable body and reduces the service life of the external cable;

④ In the natural environment exposed by the external prestressed reinforcement system, it is susceptible to erosion, fire, and mechanical damage;

⑤ There is inconsistent deformation between the external cable and the beam body, and the force deformation is more complicated in the limit state, which makes accurate calculation difficult or too cumbersome.

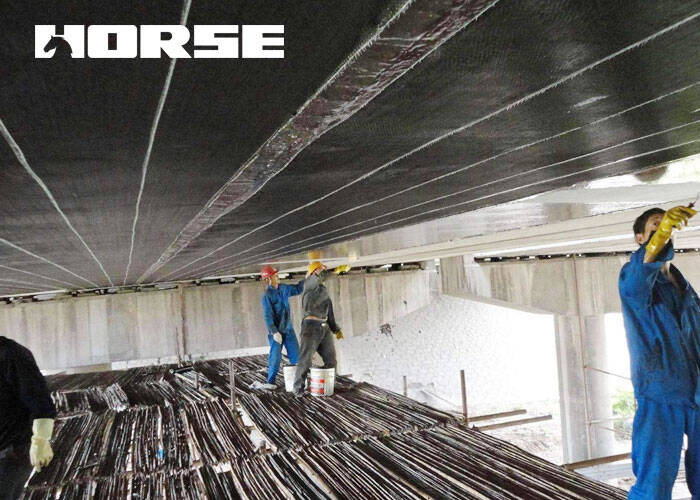

2) Pasting carbon fiber or steel plate reinforcement method

This kind of reinforcement method is to bear part of the tensile stress by pasting carbon fiber or steel plate in the tension zone of the beam body, which improves the stiffness of the beam body and changes the stress distribution state of the bridge structure, thereby improving the flexural bearing capacity of the bridge.

The advantages are: simple design, easy construction, short construction period, small amount of on-site work, small increase in dead weight, little or no damage to the original structure, and low reinforcement cost. Among them, the bonding steel reinforcement method can increase the flexural bearing capacity of the bridge by 20% to 30%, and the stiffness can be increased by 5% to 15%.

This reinforcement method belongs to the passive reinforcement method, that is, the distribution of the stress-free material before the live load is applied to the bridge. In the normal use stage after the live load is applied, although stress is generated in the adhesive material, it can bear part of the load, but the stress level is low, the strength of the reinforcing material cannot be fully utilized, and the strength utilization rate is low. Only when the steel in the tension zone of the original beam is close to yielding or yielding, that is, when the ultimate failure state is reached, a large stress can be generated, but the reinforcing material itself often fails to reach the ultimate state. Therefore, this method has a limited increase in the bearing capacity of the bridge during normal use, and it is mostly used in actual reinforcement projects to strengthen the bearing capacity. Moreover, this reinforcement method does not greatly increase the rigidity of the beam, and cannot significantly reduce the deformation of the beam under the action of live load, which is not suitable for the high rigidity requirements of railway bridges. In order to improve the reinforcement effect, the construction needs to interrupt the traffic. The traffic can only be opened when the bonding resin has sufficient strength. The interruption time depends on the construction speed and the strength growth rate of the bonding resin, which has a greater impact on the traffic. In addition, anti-corrosion needs to be considered when using steel plates. The later maintenance costs are high, and the steel plates are rigid, and the bonding surface is easy to vacate, so the fatigue resistance is poor. Although the carbon fiber material has good anti-corrosion performance, it is not suitable for use in high temperature or fire-prone environment.

3) Enlarging the cross-section and reinforcing the method of reinforcement

The load-bearing cross-sectional area is increased by laying steel bars on the bottom, side or bridge surface of the beam and pouring concrete to connect with the old concrete surface. Increasing the moment of inertia or bending stiffness of the section, thereby reducing the maximum tensile stress of the beam under load, or keeping the maximum tensile stress unchanged, can increase the bearing capacity, and finally achieve the purpose of reinforcement. This reinforcement method is also a passive reinforcement method. The original section needs to bear all its own weight before and after reinforcement. The tensile and compression zone steel bars and concrete of the original section already have a certain stress or strain when the bridge is not subjected to live load, and the increased section only bears part of the live load.

The advantages of this reinforcement method are the durability of the structure after reinforcement, the low maintenance cost in the later period, the improvement of interface stiffness and the change of natural vibration frequency. The disadvantage is that the on-site construction is complicated, the quality control is difficult, and it has a great impact on the traffic. The reinforcement effect is greatly affected by the original structure of the bridge. Increasing the self-weight of the cross section will increase the burden on the pier and abutment. The connection between the new and the old concrete interface area is poor and has many defects.

Comparison of different reinforcement methods

The selection of suitable bridge reinforcement methods for heavy-load railway transportation should meet the following requirements:

First of all, we must ensure that the impact on normal transportation is as small as possible. As my country's heavy-haul railway transportation is very busy and the direct economic loss caused by interruption of traffic is huge, it is best not to interrupt the traffic. From this point of view, the best option is the external prestressed reinforcement method, and because the tensioning takes a very short time, if the measures are taken properly, the time of opening the skylight can be used to carry out, which can minimize the impact on traffic.

Second, the requirements for reinforcement effects. From the perspective of the safety of the reinforced bridge, the deflection should be as small as possible, and should meet the requirements of the "Bridge Regulations" to avoid excessive deflection and increase the risk of train derailment: In addition, the proportion of railway live load is large, which requires high bridge stiffness. ; From the perspective of bearing capacity, ensuring sufficient bearing capacity is the most basic requirement for bridge reinforcement. Therefore, the order of selecting the reinforcement method from the deflection point of view is as follows: external prestress>increased section and reinforcement>bonded carbon fiber or steel plate. The order of selecting the reinforcement method from the perspective of stiffness is: increasing section and reinforcement> external prestressing> pasting carbon fiber or steel plate. From the perspective of bearing capacity, the order of selecting the reinforcement method is: external prestressing>increasing section and reinforcement>bonding carbon fiber or steel plate.

Third, the requirements in terms of construction technology and cost. Under the premise of ensuring quality, the selected construction process is as simple as possible, and the reinforcement cost is as low as possible. The order of selecting the reinforcement method from the perspective of construction technology is: pasting carbon fiber or steel plate> external prestressing> increasing section and reinforcement. From a cost point of view, the lowest cost of bonding carbon fiber or steel plate is the best choice. However, considering the total cost, including the loss of railway transportation caused by the interruption of traffic, the external prestressed reinforcement method is still the lowest.

The comparison between several reinforcement methods is listed in the table. Combining the requirements of the above railway concrete bridges for the reinforcement methods and the comparison from different angles, it can be concluded that the external prestress reinforcement method is the best method to improve the bearing capacity of heavy-duty concrete railway bridges.

| Structural reinforcement method | Reinforcement cost | Decreased deflection | Increased stiffness | Improved carrying capacity | Construction technology | Interrupted traffic time |

| External prestress | middle | obvious | generally | Significantly | generally | A few hours (prestressed tension) |

| Paste carbon fiber or steel plate | Low | Basically unchanged | Slightly | generally | simple | 1-2 days (adhesive curing) |

| Increase section and reinforcement | high | generally | constant | obvious | complex | A few days (concrete curing) |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.