Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

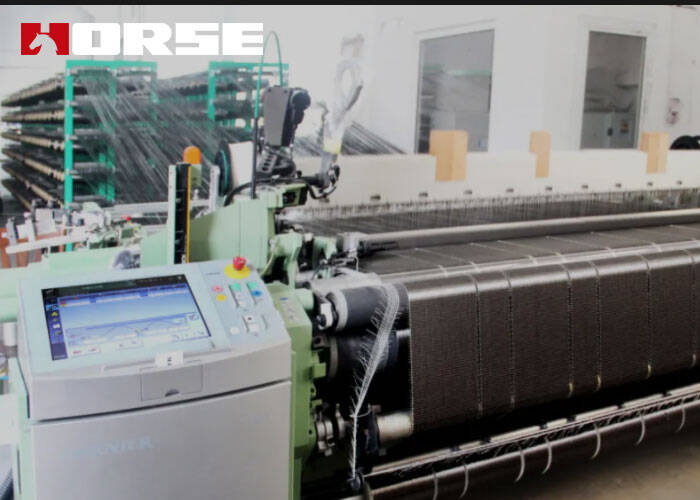

Rolls Royce in the loom-the high-tech behind high-quality carbon fiber cloth

On June 28, 1919, Germany signed the "Versailles Contract", announcing the official end of the First World War. The contract imposed strict restrictions on Germany’s armaments. The navy must not exceed 15,000, the army must not exceed 100,000, capital ships and submarines, the establishment of an air force, and the possession of aircraft, tanks, and heavy artillery are prohibited.

Dornier, the world-famous aircraft manufacturer, had to reposition and start manufacturing textile machinery after World War II.

The rapier loom developed in 1967 and the air-jet loom launched in 1989 were an important milestone for DORNIER to become the only world-renowned loom manufacturer in Germany.

Horse Construction company introduced a German intelligent production line in 2014. So far, it has been equipped with 9 advanced reinforcement material production lines. These include five German-imported DORNIER intelligent carbon fiber cloth professional looms and a number of independently developed supporting equipment and processes. The annual production capacity of carbon fiber cloth is 5 million square meters, and the daily storage of carbon fiber cloth is not less than 100,000 square meters.

HORSE CONSTRUCTION independently developed a constant tension creel system to make each bundle of carbon filaments have a constant and even tension during the weaving process, ensuring that the braided carbon cloth is straight and free of bends, and can exert the strength of each carbon filament.

Fully automatic computer intelligent control, the broken wire will stop automatically, the length of each roll is 100.02 meters, and there is no shortage of shortness.

HORSE CONSTRUCTION uses imported aviation-grade carbon wire, which is flexible in texture, moderately soft and hard, fits well with the components, and fully exerts its strength. Super long continuous without joints, continuous tow, cutting is not loose, no fuzz flying, workers have no allergens.

Germany imported DORNIER carbon fiber cloth professional loom and HORSE CONSTRUCTION independently developed a constant tension creel system, which makes the quality of HORSE CONSTRUCTION carbon fiber cloth far ahead in the industry. With a market share of about 30% in China, it is firmly in the leading position in the industry. Its products are exported to 60 countries and regions in the world, and it always guards the lives of billions of people. Over 50% of new customers are sincerely recommended for conversion by old customers.

HORSE CONSTRUCTION always adheres to the principle of customer first, integrity-based, and its mission is to manufacture the highest quality reinforcement materials, eliminate potential safety hazards of concrete structures, and save lives and buildings.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.