Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How To Bond Carbon Fiber To The Beam's Oblique Section Under Shear Reinforcement?

There are two main types of reinforcement for the oblique section of the beam. One is the insufficient shear capacity of the oblique section of the original concrete beam; the other is the insufficient shear capacity of the oblique section of the beam due to the reinforcement of the normal section.

For the reinforcement of the normal section of the beam, the ductility is greatly reduced when the bending failure occurs, but it is still more ductile than the shear failure. Therefore, the carbon fiber reinforced beam should still avoid shear failure.

Existing tests have shown that the carbon fiber attached to the bottom of the flexurally strengthened beam has almost no effect on its shear capacity. Therefore, when calculating the load-bearing capacity of the oblique section of the beam, the influence of the flexurally strengthened carbon fiber attached to the bottom of the beam is ignored.

Carbon fiber oblique section reinforcement method

The fiber direction is generally arranged along the direction that can effectively control the shear cracks. For the shear reinforcement of the oblique section of the beam, there are three main methods for bonding carbon fiber.

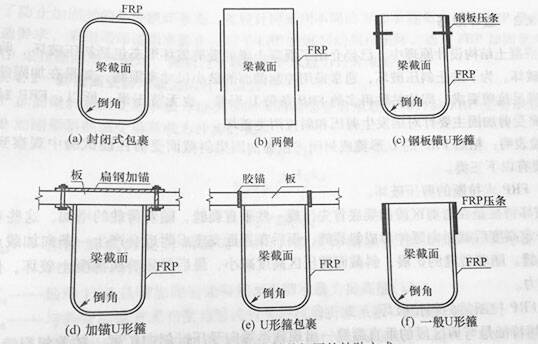

1. The entire beam section is enclosed with carbon fiber strips, as shown in the figure (a) below. This kind of method is less easy to peel off, and the reinforcement effect is better. However, in most cases, the beam and the floor are cast in one piece and cannot be enclosed in a closed package. The scope of application of such methods is relatively small.

2. Paste carbon fiber on both sides of the beam, as shown in the figure (b) below. This type of method is prone to peeling, the shear bearing capacity is not improved much, and the reinforcement effect is poor. Generally, this method is not suitable.

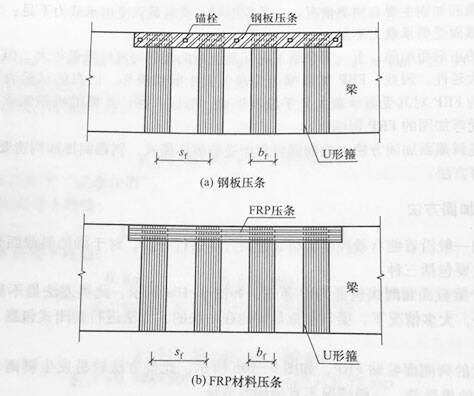

3. Paste carbon fiber strips on the side and bottom surface (three sides) of the beam, that is, paste the U-shaped hoop, as shown in the figure c-f above. This kind of method has better reinforcement effect and wider application. However, this reinforcement method may peel off at the free end of the U-shaped hoop, and the end of the U-shaped hoop needs to be anchored. The longitudinal bead method is currently the commonly used anchoring method, as shown in the figure below.

Although all the three methods can improve the shear capacity of the oblique section of the beam, the fully wrapped section is more effective, followed by the U-shaped wrapping, and the effect of pasting on both sides is poor. At present, two reinforcement methods are generally adopted in engineering: closed wrapping or pasting U-shaped hoop.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.