Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Embedded Steel Bar in Foundation Reinforcement and Reconstruction Engineering

Project Overview

This project is an upgrade and transformation project of an electric precipitator in a power plant. The power plant is located in Jiangjin District, Chongqing City. The seismic fortification intensity is 6 degrees. The designed seismic group is the first group, and the foundation design grade is B. ±0.000m takes the same original construction drawing of the electrostatic precipitator, and the absolute elevation is 206.00m. The foundation form of the original electrostatic precipitator support is a bored pile, the diameter of the pile body is 600mm, the bearing layer at the end of the pile is moderately weathered sandy mudstone, and the characteristic value of the vertical bearing capacity of a single pile is 1400kN. The concrete strength of the original electrostatic precipitator support column and cap is C25. It is proposed to increase the height of the original electrostatic precipitator, and add 2 electric fields to the back of the original electrostatic precipitator, the load will increase and the load position will be changed.

Recheck the foundation of the original electrostatic precipitator. According to the rechecked calculation results, the vertical bearing capacity of the original 2-pile cap foundation PC3, PC17, PC18, and PC19 does not meet the requirements and needs to be reinforced.

Foundation reinforcement plan

Because the original foundation is a bored pile foundation, the foundation should be reinforced with a new pile foundation. Due to the influence of existing buildings (structures), pile-forming machinery and equipment such as static pressure, hammering, and vibration cannot enter the site, and precast pile foundations cannot be constructed. Combined with the characteristics of the soil layer of this project, the groundwater is relatively poor and the conditions for manual digging are better, so the design uses manual digging and pouring piles to reinforce the original foundation.

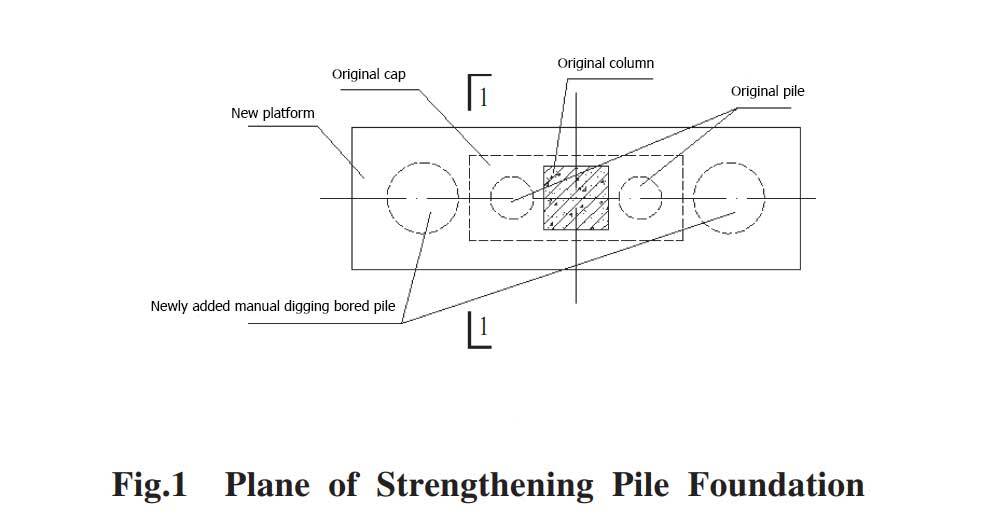

The specific reinforcement method is to add a manual digging and filling pile at each end of the original two pile cap foundation. The diameter of the newly-added manual digging cast-in-place pile is 1000mm, and the supporting soil layer at the end of the pile is moderately weathered sandy mudstone. According to the calculation results, the characteristic value of the vertical bearing capacity of a single pile is 1700kN. The surrounding and upper part of the original reinforced concrete platform shall be covered with a new reinforced concrete platform. The newly added reinforced concrete platform will effectively connect the new foundation piles with the original reinforced concrete platform and column (see Figure 1). The newly-added manual digging and pouring piles and caps are made of concrete with a strength grade of C30. The longitudinal reinforcement of the newly added platform and the outer stirrup are HRB400-grade steel bars, and the internal stirrups are HRB335-grade steel bars.

Conclusion

The renovation project was put into use after the completion and acceptance in 2015, and the structure is in good condition and meets the requirements for use.

With the increase in the reinforcement of old houses and the renovation of workshops, the technology of planting steel bars has been increasingly used in the connection of new and old concrete joints. As an important load-bearing capacity index of the section, its calculation is a key consideration in the design. Since the current domestic regulations have not made corresponding regulations, the existing research results and corresponding foreign regulations can be referred to when designing and calculating. Select the appropriate theoretical formula, carry out the planting bar design under the comprehensive control of the bearing capacity calculation and structural requirements, and leave an appropriate margin to ensure the safety of the structure.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package for anchoring