Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber Reinforced Polymer About Bridge Reinforcement Engineering

A lot of practice has proved that because fiber reinforced polymer (FRP) composite materials can provide the strength, flexibility and other properties necessary for repairing and strengthening concrete structures, it is effective to repair and strengthen concrete structures, and its application is more and more extensive.

The current situation of the reinforced concrete bridge of a bridge that has been in operation for 27 years under the extreme vehicle load was investigated, and it was reinforced with CFRP cloth, and the crack development was monitored after reinforcement. In order to determine the flexural performance of reinforced concrete beams before and after reinforcement with CFRP cloth, a finite element model of reinforced concrete bridge span was established to analyze the relationship between bending moment and curvature.

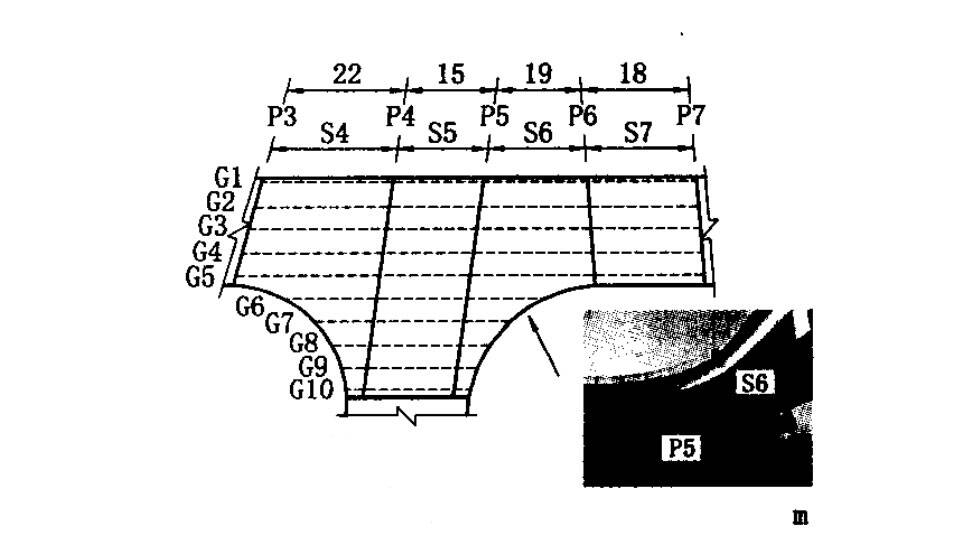

A bridge is a multi-span bridge, the side span main beam is a steel beam and concrete slab combined structure, and the middle span main beam is a cast-in-place reinforced concrete structure. The bridge has been in operation for 27 years and is responsible for two-way 4-lane traffic. The layout of the cast-in-place reinforced concrete mid-span (span 4-7). The total height of a typical reinforced concrete T-beam is 1680mm, the web width is 460mm, and the flange thickness is 216mm. Due to the difference in geometry and the size of the load, the detailed stiffening structure of the reinforced concrete beams in each span is different.

When a heavy-duty truck passed, the bridge was inspected at a height of 12m from the ground, and it was observed that there were obvious cracks on the bottom of the reinforced concrete beam. Especially the 4th, 6th and 7th spans, and the most serious cracks are located near the middle of the main beam.

Carbon fiber reinforced polymer about bridge reinforcement engineering

1. Surface treatment

Since bonding is the key to applying carbon fiber reinforced polymer cloth, the condition of the bonding surface is very important. In order to make the carbon fiber reinforced polymer cloth and concrete bond firmly, all impurities, loose concrete and other contaminants must be removed from the concrete surface. Although this process is simple, it takes more time and is usually completed with hand tools.

2. Surface strength inspection

In order to prevent the premature failure of the carbon fiber reinforced polymer system, the tensile strength of the concrete surface needs to be tested. According to the ACI specification, the bond strength of concrete can be verified through a tear test. The tear test should be conducted at random locations on the concrete surface. In this case, the concrete surface must have the minimum tensile strength specified by the carbon fiber reinforced polymer CFRP cloth manufacturer, which is 1.4 MPa.

3 Apply carbon fiber reinforced polymer CFRP cloth

The application of carbon fiber reinforced polymer CFRP cloth includes the following processes:

① Use a trowel or spatula to apply the mixed epoxy resin to the surface of the concrete to reach the specified thickness;

② Apply the mixed epoxy resin to the carbon fiber reinforced polymer CFRP cloth;

③Apply the carbon fiber reinforced polymer CFRP cloth to the cracked concrete surface;

④ Roll the carbon fiber reinforced polymer CFRP cloth with a hard roller until the adhesive is extruded on both sides;

⑤Remove excess adhesive.

When pasting, use a clamp to fix the carbon fiber reinforced polymer CFRP cloth at the position to be applied along the direction of the main beam. After the epoxy has taken effect, remove the clamp.

4 Crack monitoring after reinforcement

After the bridge reinforcement was completed with carbon fiber reinforced polymer(CFRP) in October 2006, the crack propagation and trend of the reinforced concrete main girder were monitored. A crack monitor was installed in the area where the main beam was damaged. The crack monitor is composed of two overlapping plates, one of which has a black background and is covered with a white millimeter grid; the other is transparent, with a red crosshair in the center of the grid. Any change in the crack will cause the crosshairs to move away from the original position of the grid. As of July 2009, no changes in cracks have been observed.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.