Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Strengthening Concrete Beams for Shear with CFRP Sheets

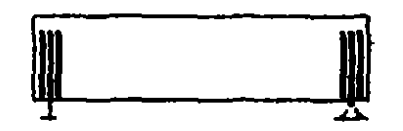

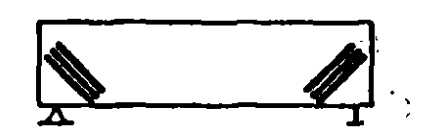

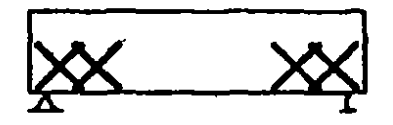

The shear reinforcement form and direction of CFRP sheets reinforced beam

CFRP sheet reinforcement for beam shear reinforcement adopts carbon fiber for shear reinforcement of beams. The carbon fiber L-shaped plate is adopted. There are mainly the following reinforcement forms: closed paste; U-shaped paste; side paste. The characteristics of several reinforcement methods are shown in Table 1.

| Reinforcement form | Closed paste | U-shaped paste | Side paste |

| Reinforcement features | The CFRP sheet is closed and pasted along the cross-section, and there should be enough overlap length on the pressure surface. Lap on the pressure surface is to minimize the relative deformation between the carbon fiber and the concrete along the fiber direction. When the pressure surface cannot be overlapped, it can also be overlapped on the tension surface. | The three sides of the u-shaped paste should be continuous fibers, usually two sides and a tension side. When this is not possible, it can also be two sides and a pressure side. | CFRP sheet is only pasted on the two sides (sheared surface) of the component. |

| Advantage | The least prone to anchoring failure, the most effective, and can be used as a mechanical anchor for flexurally reinforced carbon fiber. | The U-shaped bottom anchor garden is better, and it is not prone to peeling damage, and is more effective. It can be used as a mechanical anchor for bending and strengthening carbon fiber. | It is the easiest to achieve, and carbon fiber can be saved for components that require less improvement in shear capacity. |

| Disadvantage | Impossible or difficult to achieve to beam | The free end of the U-shaped carbon fiber may require mechanical anchoring. | Prone to peeling damage, the effect is not as good as closed paste and u-shaped paste. |

| Supplement | In order to avoid stress concentration at the corners and cause CFRP sheet damage or peeling, the corners of the components should be polished to fillet, and the radius of the outer surface of the fillet should not be less than 20mm. For U-shaped and side sticking, the free end of the carbon fiber should be properly anchored if necessary | ||

CFRP sheet reinforcement direction

There are three bonding directions for carbon fiber

①Vertical direction: The fiber direction is perpendicular to the axis of the component.

②45 degree direction: the fiber direction and the axis of the component form an angle of 45 degrees.

③Two-way pasting (45 degrees and 135 degrees): The fiber direction is 45 degrees and 135 degrees with the axis of the component.

The advantages and disadvantages of reinforcement with different fiber directions are shown in Table.

①Vertical direction: The fiber direction is perpendicular to the axis of the component.

advantage: Easiest to achieve effective for both shearing forces

disadvantage: Not as effective as diagonal crack control

②45 degree direction: the fiber direction and the axis of the component form an angle of 45 degrees.

advantage: Effective for shear crack control

disadvantage: It is impossible to achieve U-shaped paste and closed paste with unidirectional fiber cloth

③Two-way pasting (45 degrees and 135 degrees): The fiber direction is 45 degrees and 135 degrees with the axis of the component.

advantage: Most effective for crack control, effective for shear forces in both directions

disadvantage: Maximum fiber consumption

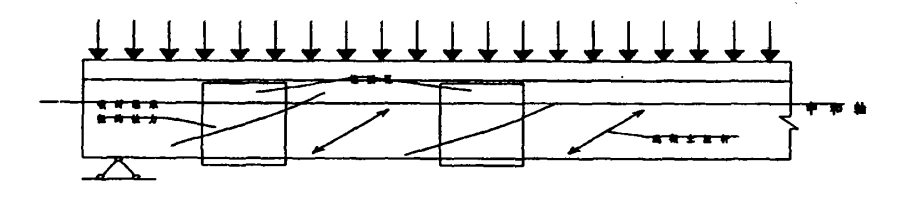

CFRP sheet reinforcement mechanism

As shown in Figure 1, the mechanism of using CFRP sheet to strengthen beams for shear resistance mainly has the following points:

① The CFRP sheet acts as an additional stirrup, bearing the tensile force.

②The concrete between the diagonal cracks forms a diagonal tie rod.

③The CFRP sheet is anchored in the compression zone above the neutral axis, or an enclosed hoop is formed by additional anchoring, which effectively resists shear.

Basic principles of CFRP sheet reinforcement

The fiber direction of the CFRP sheet should be perpendicular to the axial direction of the component. The closed paste form should be preferred, and the u-shaped paste should be preferred to the beam body. When the CFRP sheet is arranged in strips, the net spacing should not be greater than 0.7 times the maximum stirrup spacing, and the number of strips should be one layer. The sticking height of u-shaped sticking and side sticking should be the height of the component section.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.