Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Construction Technology and Effect of Carbon Fiber Reinforcement Wharf Concrete

The continuous structural damage and material deterioration of the port wharf structure in the daily and frequent operation process leads to reduced functions, which leads to the failure of the terminal's operational capacity to be guaranteed, and there is a danger of insufficient safety and durability.

At present, in the construction of wharf maintenance and reinforcement, in addition to grouting the cracks, the main reinforcement method is to paste carbon fiber composite materials. Carbon fiber cloth and supporting dipping glue are used together to form a carbon fiber composite material. Carbon fiber cloth has high tensile properties, can improve the bearing capacity and strength of concrete structures, and can also avoid the further development of concrete cracks. Through the exploration of the construction technology of pasting carbon fiber cloth composite material and the analysis of the reinforcement effect, it can be understood that this type of reinforcement construction is widely used in the current structural reinforcement construction and the effect is obvious.

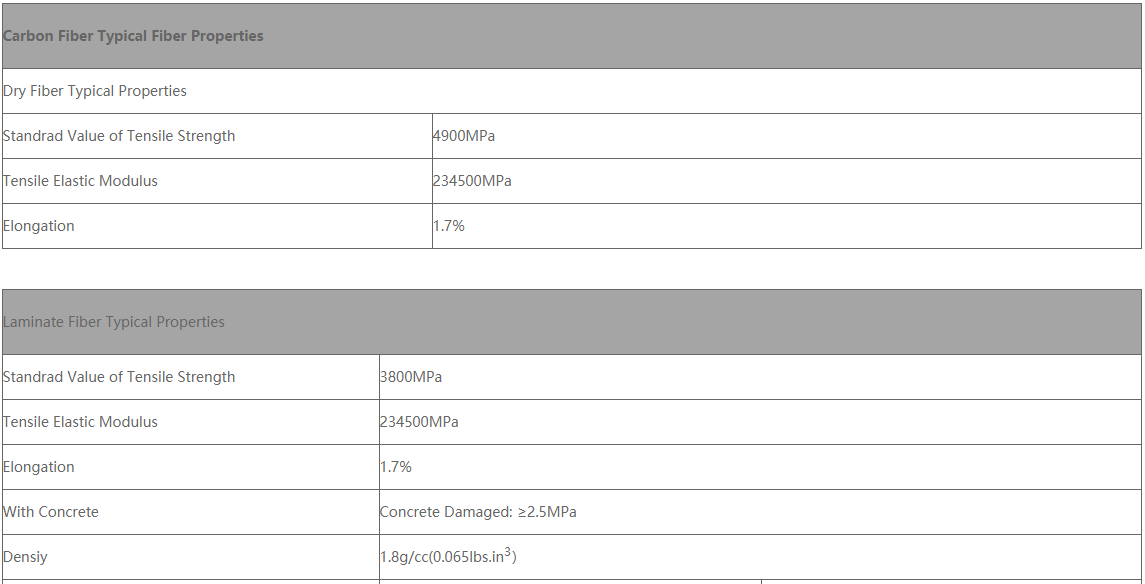

1 Material properties

The reinforcement of a wharf adopts high-strength grade I carbon fiber cloth with a design thickness of 0.167mm and a unit mass of 300g/m2. Both U-shaped hoop and bead are made of high-strength grade I carbon fiber cloth. Its performance indicators must meet the specifications. Table 1 shows the performance requirements of the high-strength grade I carbon fiber cloth required by the design and the actual performance test results of the purchased carbon fiber cloth.

The performance index of the adhesive for carbon fiber composite materials must meet the specifications. Do not use unsaturated polyester resin and alkyd resin as impregnating and bonding adhesives. Because beams and pile caps are easily affected by moisture, moisture-curing adhesives that meet the requirements should be used. The positive tensile bond strength with dry surface concrete is ≥2.5MPa, and the failure form of the carbon fiber positive tensile bond strength detection should be concrete cohesive failure.

Before the construction of the wharf reinforcement, the materials were witnessed and sampled for inspection, and the material performance test of Horse high-strength carbon fiber cloth was carried out. The results showed that all the indicators were in compliance with the specifications. Therefore, the construction process and construction quality will directly determine whether the reinforcement effect can achieve the expected effect of the design, so as to achieve the purpose of reinforcement.

2 Construction technology

The principle of strengthening the concrete components of the wharf is to paste carbon fiber cloth on the surface of the component after the repair of the original component is completed to improve the load-bearing capacity of the beam and slab components and achieve the effect of strengthening the wharf. At the same time, the carbon fiber cloth outsourcing the dock components can protect the original structure from corrosion. The specific construction process is as follows:

Unload the load → treatment of the bottom layer → coating the bottom layer of resin → sticking carbon fiber cloth → inspection → surface protection.

1) Unload the load: stop the wharf operation in the construction area before reinforcement to ensure that the components are in a state of unstressed and the effect of reinforcement.

2) Bottom treatment: First, the defects such as damage and cracking on the surface of the concrete should be removed and repaired, and the corroded steel bars should be derusted. The repair glue will level the surface of the concrete. Rinse the floating dust on the surface before applying the primer, and dry it. For the tidal splash area, you can use fire to keep the surface dry before proceeding to the next step of construction.

3) Coating the bottom layer resin: prepare according to the product usage requirements; the bottom layer glue is evenly coated on the concrete surface. To ensure the bonding effect, the carbon fiber cloth should be pasted as soon as possible after the bottom layer resin is cured.

4) Paste the carbon fiber: First, cut the carbon fiber cloth according to the width requirements of the design document, and mix the adhesive according to the preparation ratio of the product description. Then apply the dipping glue evenly on the sticking area, and pay attention to the corners and overlapping parts. The carbon fiber cloth is pasted from one side of the component, and the other side is stretched vigorously. It is repeatedly pressed and swept with a brush to avoid the generation of air bubbles and make the sizing glue fully soak the carbon fiber cloth. After the surface of the carbon fiber cloth is dry, the next layer should be pasted. Repeat the above steps for multilayer pasting.

5) Inspection: In order to ensure the bonding quality between carbon fiber cloth and concrete, after the bond strength is reached, a carbon fiber drawing instrument can be used to test the positive tensile bond strength of carbon fiber cloth, and the corresponding test results can be determined with reference to the specification.

6) Surface protection: The carbon fiber cloth should be protected within 24 hours after all construction is completed, to prevent scratches on the reinforced surface, and pay attention to moisture. After curing, the carbon fiber surface should be protected by painting with anticorrosive paint.

7) Precautions for construction of carbon fiber cloth

(1) Before surface treatment and pasting of carbon fiber cloth, the reinforcement position, the width of the carbon fiber cloth and the number of cloth strips should be confirmed. The cloth strip interval should be carried out according to the design requirements.

(2) The bottom resin and adhesive should be weighed according to the proportion specified in the product instructions when preparing, and mixed evenly. There should be no oil and impurities in the mixing container. Before construction, a plan should be made to avoid excessive waiting time that will cause the glue to fail and cause waste.

(3) Pasting carbon fiber cloth is a key process in the construction of the wharf reinforcement. It must be completed by a professional construction team familiar with the construction process, and it should be carefully organized, carefully constructed, and strictly control the construction quality of the process

3 Analysis of reinforcement effect

Taking the concrete carbon fiber reinforcement construction of a wharf beam and slab as an example, the reinforcement effect was explored. The selected materials of the project were sent for inspection by witness sampling, and the test results were all qualified. The construction part is strictly implemented in accordance with the formulated construction plan, and the key procedures such as the preparation, painting and pasting of the adhesive and maintenance are strictly controlled.

3.1 Detection of reinforcement effect

In order to confirm the reinforcement effect, after the bond strength is reached, the carbon fiber positive tensile bond strength test is performed. The detection steps are as follows:

1) Surface treatment: Randomly select the detection position, and polish the surface of the detected position to ensure that the surface is dry and smooth.

2) Cutting and pre-cutting: circular cutting from the carbon fiber cloth reinforced surface to the inside of the concrete, the cutting depth is 5-10mm, and the width is about 2mm. The shape of the pre-cut seam is a circle with a diameter of 50mm.

3) Paste the steel standard block: use high-strength, fast-curing adhesive to paste the steel standard block, the positive tensile bonding strength of the adhesive should be greater than the positive tensile bonding strength of the structural adhesive pasted with carbon fiber sheets. The steel standard block should be fixed immediately after pasting.

4) Load at a uniform speed of 1500~2000N/min, record the peak value of the positive tensile bond strength, that is, the load value when the bonding surface of the carbon fiber cloth and the concrete is damaged, and observe the failure mode. Through the test, 5 groups were randomly selected on site. The strength of each sample in each group ranges from 2.51 to 3.12 MPa, and each sample is concrete cohesive failure, which meets the requirements of the standard CECS146:2007 Article B4.4. .

3.2 Analysis of reinforcement effects and suggestions

In the carbon fiber cloth reinforcement construction of a wharf, the bonding ability of carbon fiber cloth and concrete meets the design requirements, and the sample samples are all concrete cohesive failure. However, if the old wharf is reinforced and reconstructed, the concrete performance will decrease significantly. If the carbon fiber positive tensile bond strength test is performed, the concrete cohesive failure will occur, but the bond strength is low. Therefore, the actual reinforcement effect should be tested during the inspection process. According to the actual situation of the building, other testing methods are used for verification when necessary.

According to the requirements of the carbon fiber cloth paste position and the number of layers in the design documents, the bending and shear resistance of the wharf are calculated. It is calculated that the flexural and shear resistance of the pier beams and slabs reinforced with carbon fiber cloth can meet the requirements of the pier's bearing capacity, which improves the safety and stability of the overall operation of the pier.

Carbon fiber material itself has the characteristics of high strength, high elastic modulus, light weight and good corrosion resistance. When the carbon fiber cloth is pasted, the impregnating glue coated on the surface is modified epoxy resin, which has good corrosion resistance and aging resistance. After curing, the adhesive layer is wrapped on the surface and inside of the carbon fiber cloth, forming a whole with the concrete structure to be stressed. Therefore, the immersion of the carbon fiber cloth and the matching modified epoxy adhesive by seawater will not affect its durability. In order to improve the anti-erosion and anti-wear performance of carbon fiber cloth in the rising and falling of sea water, we can consider painting the surface of the entire reinforced area with an anti-corrosion coating for further protection measures, which can strengthen the protection of the wharf and improve the durability.、

4 Conclusion

Taking a foreign trade wharf reinforcement project as an example, a brief analysis of the construction technology and reinforcement effect detection of carbon fiber composite materials is carried out. This kind of reinforcement construction application has been very extensive, and the conventional application is mainly in the concrete structure. The reinforcement method has the advantages of simple construction process, low cost, short construction period and obvious reinforcement effect. On the premise of optimizing the construction process and strengthening the construction quality of key processes, the effect of concrete reinforcement can be ensured, and the performance of the concrete structure can be effectively improved, thereby enhancing the safety and durability of the wharf.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.