PCCP Rehabilitation

Rehabilitation with Carbon Fiber-Reinforced Polymer(CFRP)

Horse carbon fiber is an economical system for strengthening corrosion-damaged pipes to significantly increasing the strength of the pipe.

Large-diameter pre-stressed concrete cylinder pipes (PCCP) are widely used to carry water. PCCP consists of a steel cylinder embedded in a concrete core, which is helically wrapped with high-strength, hard-drawn wire after curing. The wire is embedded in a thick cement slurry and coated with a dense cement mortar.

Pre-stressed concrete cylinder pipes (PCCP) may have the following problems after long-term use:

1) Longitudinal and circumferential cracks

2) Corrosion

Horse carbon fiber is an economical system for strengthening corrosion-damaged pipes to significantly increasing the strength of the pipe.

Advantages:

1) Application of CFRP virtually leaves the internal diameter of the pipe unchanged

2) Restores hoop and longitudinal strength

3) Can increase pipe strength

4) Installation is very fast and economical

5) Upgrade the structural capacity of an existing pipe

6) Maintains water tightness of pipe under changing conditions of original pipe

7) Long term lifecycle extension of pipeline assets

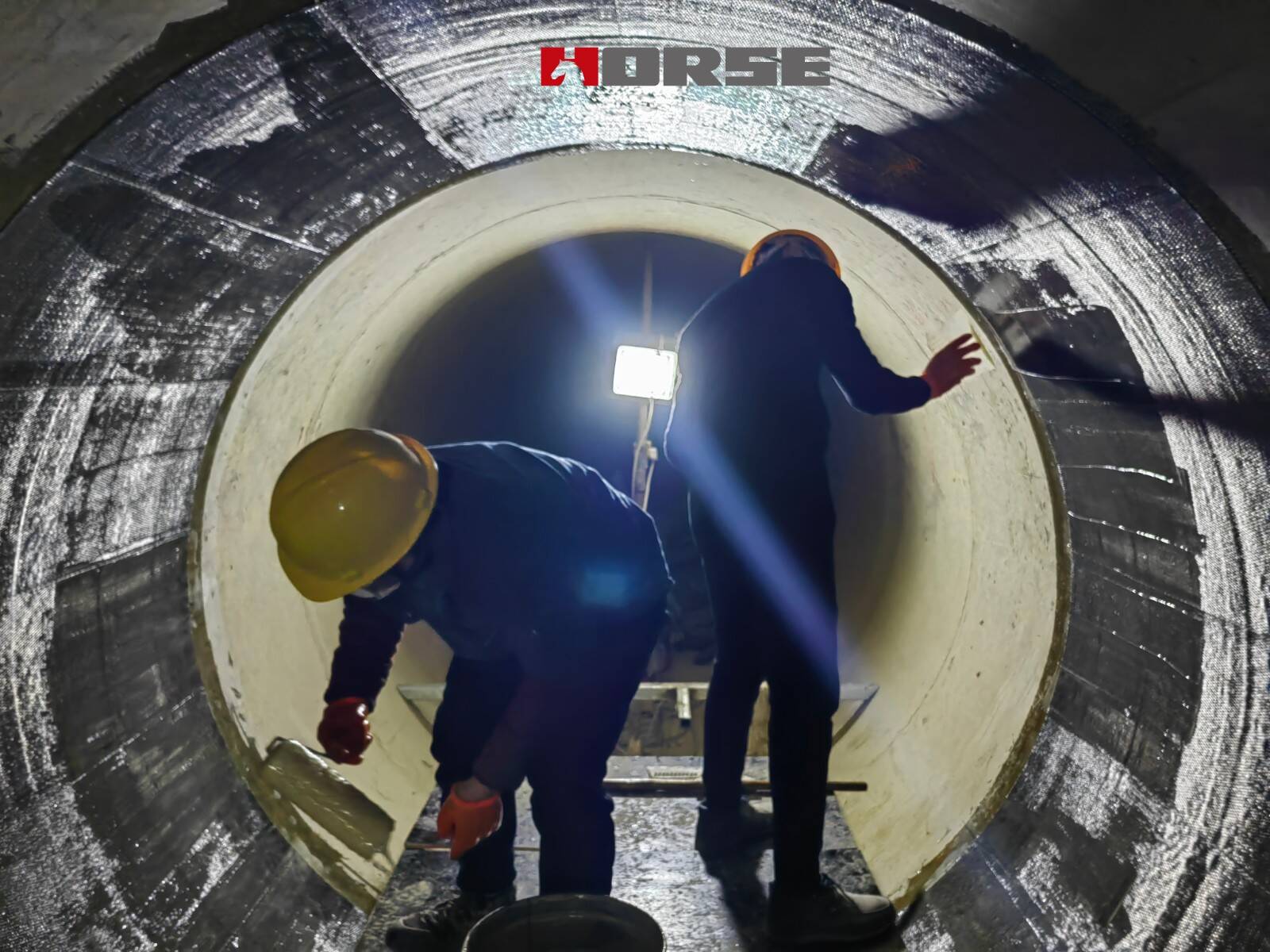

There are mainly the following steps to bonding carbon cloth inside PCCP:

Surface treatment:

Cleaning: First clean up the debris, dust, oil stains, etc. inside the PCCP pipe. You can use brooms, vacuum cleaners and other tools for preliminary cleaning to ensure the neatness of the pasting surface.

Grinding: Use a special hand-held grinding device to grind the inner wall of the pipe to remove the floating slurry, loose layer and possible rust on the surface, so that the surface of the pipe wall becomes rough and the bonding force between the carbon fiber cloth and the inner wall of the pipe is increased. After grinding, use a vacuum cleaner and other tools to clean the debris and dust generated by grinding again.

Apply primer:

Mix primer: According to the product instructions of the carbon fiber cloth adhesive used, mix the primer in proportion. Generally speaking, the primer is composed of materials such as resin, and the main agent and curing agent need to be fully stirred.

Brushing: Use tools such as rollers or brushes to evenly apply a layer of primer on the inner wall of the polished PCCP pipe. Pay attention to uniform thickness when brushing to avoid missing brushing or inconsistent thickness. The brushing range of the primer should be larger than the pasting range of the carbon fiber cloth, generally exceeding about 5 cm.

Pasting carbon fiber cloth:

Cutting carbon cloth: According to the internal size of the PCCP pipe and the part to be reinforced, cut the carbon fiber cloth into a suitable size and shape. When cutting, pay attention to keeping the carbon cloth flat to avoid wrinkles or twists.

Preparing impregnation glue: Prepare impregnation glue according to the instructions of the adhesive product. Impregnation glue is a glue used to bonding the carbon fiber cloth on the inner wall of the pipe. It is also necessary to fully mix the main agent and curing agent.

bonding: Apply the prepared impregnation glue evenly on one side of the carbon fiber cloth, and then bonding the carbon fiber cloth on the predetermined position of the inner wall of the PCCP pipe. When pasting, start from one end and slowly bonding the carbon fiber cloth flatly on the inner wall of the pipe. At the same time, use tools such as scrapers or rollers to squeeze from the middle to both sides to expel bubbles and ensure that the carbon fiber cloth fits tightly with the inner wall of the pipe.

Curing and maintenance:

Natural curing: After pasting, let the carbon fiber cloth cure in a natural environment. The curing time depends on the product instructions of the adhesive, and generally takes several hours to several days at room temperature. During the curing process, avoid collision or disturbance of the adhesive part.

Heating curing: In some special cases, if you need to speed up the curing speed, you can use heating to cure. However, the heating temperature and time must be strictly controlled according to the product instructions of the adhesive to avoid affecting the performance of the carbon fiber cloth.

Surface protection:

Apply a protective layer: When the carbon fiber cloth is completely cured, apply a layer of epoxy protective layer or other protective material on its surface to protect the carbon fiber cloth from the external environment and extend its service life.