Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The Yangtze River Bridge Reinforcement and repairing use more new advanced technical mehod: 1, Crack repair,inside and outside the box is filled with crack glue and crack injection adhesive; 2, Pre-stress tension, bridge box body; 3, Bonded steel plate in the web and outer web of the bridge box; 4, Bonding carbon fiber reinfroced polymer(CFRP)fabric,the box girder bottom plate; 5,Adding longitudinal steel trusses near the web of box girder 6,Defect repair

Project overview

Wuhan Yangtze River Bridge is located in Wuhan Yangtze River, is a large city bridge across the Yangtze River between Hankou and Wuchang, and completedin 1995 . In recent years, due to serious vehicle overload operation (formerly the Yangtze River bridge design maximum traffic volume is 60 thousand volume / day, but super saturation soon, the daily average is about 150 thousand, which peaked at 190 thousand). After ten years of use of overload, the cumulative damage of bridge makes the stiffness of the bridge has decreased, some the beam due to cracking section stress redistribution, part of the beam may work in a plastic state, does not meet the design, and part of the existing cracks continues to expand. Therefore, it is necessary to repair and strengthening.

The Yangtze River Bridge Reinforcement and repairing use more new advanced technical mehod:

1, Crack repair,inside and outside the box is filled with crack glue and crack injection adhesive;

2, Pre-stress tension, bridge box body;

3, Bonded steel plate in the web and outer web of the bridge box;

4, Bonding carbon fiber reinfroced polymer(CFRP)fabric,the box girder bottom plate;

5,Adding longitudinal steel trusses near the web of box girder

6,Defect repair.

The main parts need bonding carbon fiber reinfroced polymer(CFR) fabric of this project are bottom of the top of the box girder beam, the bottom of the floor and the inner and outer sides of the web. It is divided into three layers, two layers and single layer by carbon fiber cloth; according to the force of carbon fiber cloth: vertical and vertical. The carbon fiber cloth is started in the case of heavy weight of the bridge surface.

This project is attached to the carbon fiber fabric with the resin, the leveling material, the impregnating resin and the surface protection material.

(bridge strengthening with carbon fiber fabric(CFRP fabric))

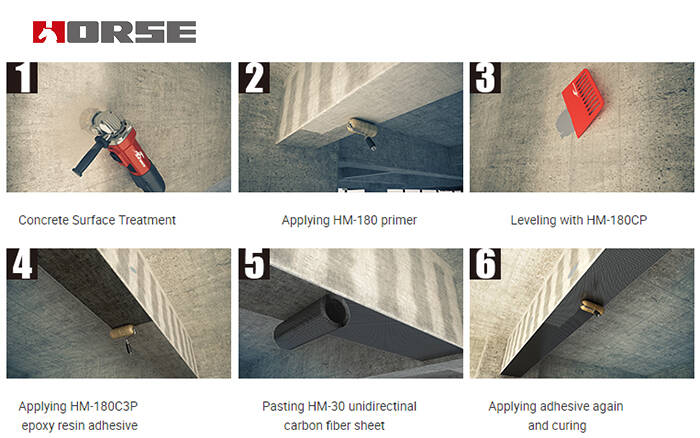

The construction method

>>The treatment of concrete surface

The cosmetic layer, oil, dirt etc. Of concrete surface should be chiseled off and then rubbed off 1 ~2 mm thick surface layer with theangle grinder, concrete components should be handled by chamfering on the corner, dust was blew out with compressed air after the completion Of polishing, and finally the surface was wiped by cotton cloth dipped in acetone, and kept dry for use. If the concrete needed to strengthen existed cracks, first choose HM-120M perfusion adhesive or HM-120L pouring crack adhesive to perfuse according to the size of crack, and then strengthen.

>>Primer construction

When construction, two components of primer A and B were weighed according to the stipulated proportion of preparing glue, and dumped into a clean container and stirred to uniformity (when mixing, best mix along the same direction to avoid the air from forming air bubbles.) Brush or roller brush was used to evenly brush on the concrete surface, after the glue surface layer dried, it should be brushed several times depending on the particular circumstances, but the coating thickness did not exceed 0.4 mm, and it should not be missed out to brush, or have flowing or bubbles, waiting for glue curing (curing time was depended on the site temperature, it was appropriate when finger felt dry, generally not less than 2 hours), then the next process was proceeded. The glue prepared every time should be used up one time during the applicable period of the glue.

>>Leveling construction

The pores and defects on concrete surface were filled by leveling adhesive.When depression area was existed, the prepared leveling adhesive was used to repair and fill through scraper embedding and scraping, the position emerging altitude difference such as the joint of templates should be filled by leveling adhesive, which tried to minimize the height difference. The treatment of corner was that it was repaired to smooth arc through leveling adhesive, its radius was not more than 20mm. After the leveling adhesive cured (curing time was depended on the site temperature, it was appropriate when finger felt dry, generally not less than 2 hours), the next process should be proceeded further.

>>Paste of carbon fiber cloth

Carbon fiber impregnated adhesive was smeared to the pasted area evenly,the corner site was more smeared appropriately. Paste after hauling carbon fiber cloth tight and alignment, use a plastic scraper or roller (a paint roller that the villus was removed outside) to roll repeatedly along the same direction, until the glue compound exuded. And then smear impregnated adhesive to the outside surface of the carbon fiber cloth evenly, and roll repeatedly, 50 that the impregnated adhesive can immerse the carbon fiber cloth in two ways, if it is multi-paste, until your fingers touch dry, the next layer of paste can be beginner. If the carbon fiber cloth needs overlapping

>>Curing and conservation

Prevent rain or moisture 24 hours after the completion of construction, and pay attention to protection against a hard Object bumping into the surface of the construction. When the average air temperature is 20 , 25 ℃ , the curing time is not less than 3 days; when the average air temperature is 10 ℃, the curing time is not less than 7 days.

>>Carbon fiber cloth surface protection, in order to avoid ultraviolet radiation of carbon fiber cloth, the surface of carbon fiber cloth outside box girder is protected by spraying cement mortar, and no ultraviolet protection is applied in the box, so no protection plan is adopted.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement