Bridge members reinforced

CFRP strenegthening

The bridge members reinforced by CFRP can greatly improve the bending and shear resistance of the beam, and can improve the stiffness and ductility of the bridge members, and play a role in restraining the cracking and reducing the deflection.

Project overview

The bridge was built in the beginning of the last century, which was built at the beginning of the 70 years. The upper structure is the assembly type reinforced concrete beam structure of the combination of the 4 of the hole span (L) and the less reinforced micro bending plate. The bridge surface is no cross beam, and the net clearance of the bridge surface is - 7 m + 2 ×0. 25 m. The bottom is constructed as a reinforced concrete double column pile pier and gravity abutment.

Disease investigation before reinforcement

Prior to the determination of in reinforcement scheme, carried out a comprehensive investigation on the status of old bridge, full bridge 4 x 5 tablets. According to the actual damage situation, we have made a detailed examination of the 2~4 piers, the 15, the main girder, the micro bending plate, the support, the pier and the subsidiary structure.

Main girder

Poor quality of construction, size of each part along the span is not consistent. A single main beam cracks were found most 51 A, crack width the width of 4mm. There are also vertical cracks, inclined cracks, horizontal cracks, oblique fracture and horizontal direction angle is 40~80 degrees. The vertical cracks are mainly distributed in the lower part of the main girder web (mainly within the range of the middle 8. 5m) and the lower width is narrow; the slanting cracks are mainly distributed in the end of the m, and the horizontal cracks are mainly distributed at the end of the beam. The local steel exposed, corrosion.

Other

The poor quality of construction micro bending plate, the bottom is very rough, there are local fine cracks. Support for the steel bearing, steel corrosion serious, there is a large erosion block off. The concrete of the main beam near the bearing has a crushing phenomenon. No. 1 abutment conical slope damage, 3 pier found an empty phenomenon. Part drainage hole inclined railing, blocking, large deck beam space, the vehicle by serious vibration and noise.

Reinforcing design

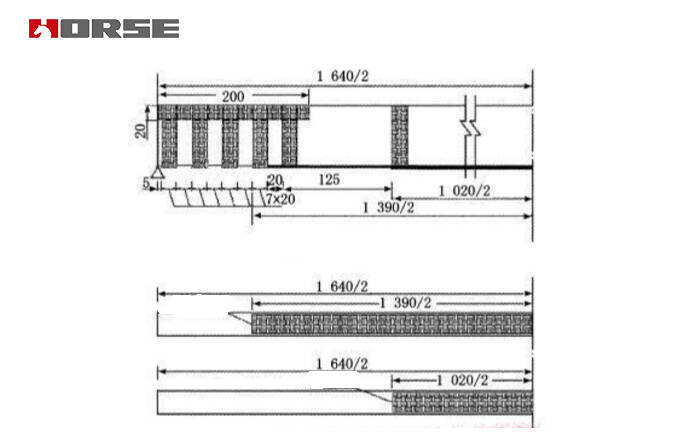

The main performance of the main beam is strengthening by 300g carbon fiber fabric. The main performance indexes are: design thickness 0.167, mm, tensile strength standard deviation, standard value of tensile strength of 40 MPa, tensile strength average value 4233, MPa modulus of elastic modulus 236 GPa. In calculation, we should take account of the cohesion between CFRP and main girder, and use the reduction factor to 0., 8 for the design value of tensile strength of materials. By calculating, mid span bottom carbon fiber material thickness to 0. 25 mm, and the 2 layer.

Strengthening key points

(1) bearing replacement

Using 5 Hydraulic Jack will be the whole hole from the top end of the whole beam synchronous, bearing replacement. After lifting the beam body, remove the original rusting support, clean up the pier and supporting stone, clean the bottom of the beam, remove grease stain and use epoxy resin to smooth. Bearing pad stone with resin concrete, with the rapid growth of strength, accelerate the construction progress.

New bearing before installation should conduct a comprehensive inspection and inspection of mechanical properties, not during the installation of new collision bearing. The new support center pivot alignment calculation beam, the bearing force uniform.

(2) crack repair

Crack width < 0. 2 mm was coated on the surface of repair, crack width > 0. 2 mm when using chemical grouting repair.

(3) carbon fiber strengthening

During construction, we should proceed from the bottom of beam to the top of beam and rib. First, the surface of the concrete is cleaned and disposed, and the bottom resin is painted, the leveling material is arranged and the surface of the component is treated, arranged and painted with the impregnated resin or the adhesive resin. When pasting carbon fiber cloth and concrete surface should be completely closed after, paste on the surface of the door handle.